Product Discription

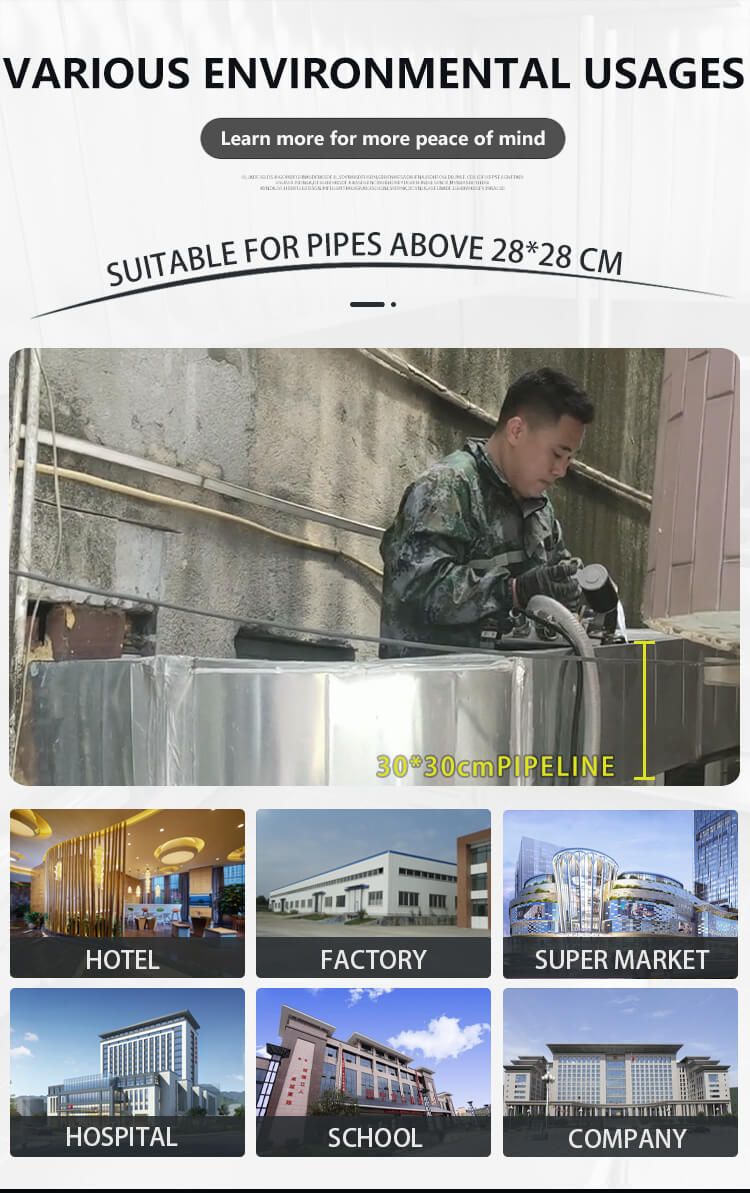

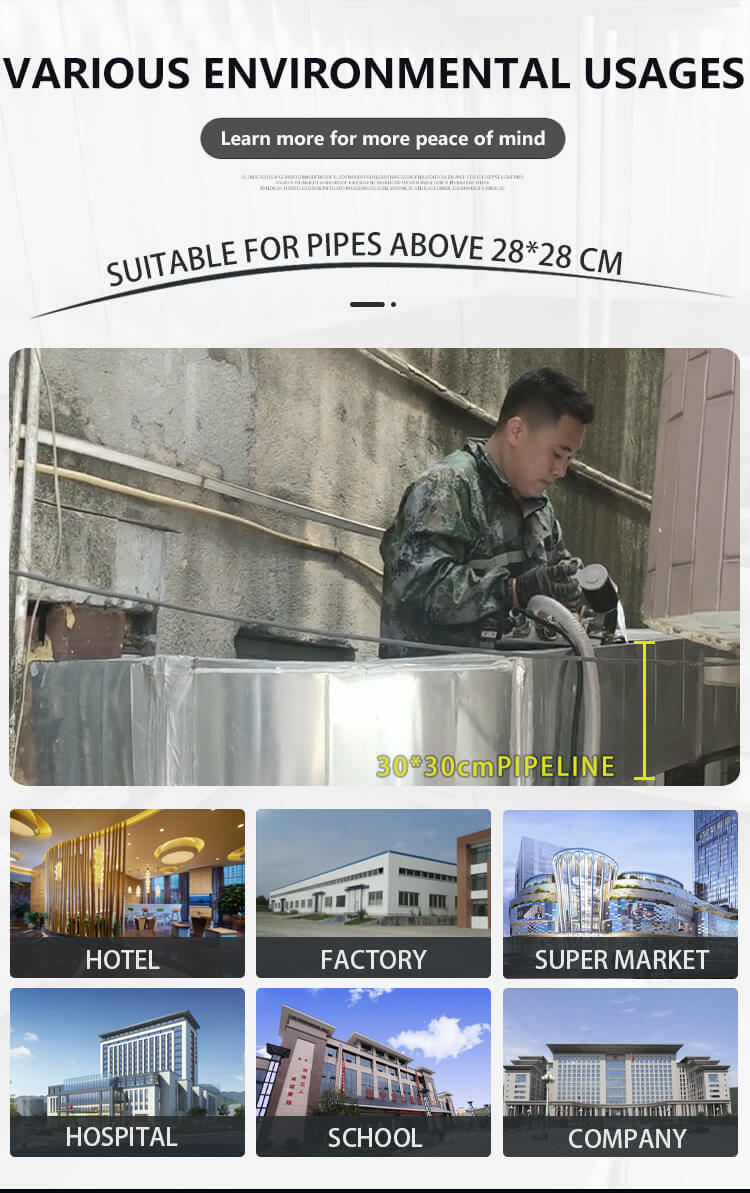

The G30 is an intelligent cleaning robot specifically designed for industrial kitchen pipelines with diameters of 28cm and above. It aims to address the pain points of traditional manual cleaning, including low efficiency, high risks, and compliance challenges. Its core objective is to achieve pipeline cleaning efficiency improvement, cost reduction, and compliance with stringent fire safety and environmental regulations through a fully automated cleaning process.

Applicable Scenarios & Industrial Kitchen Types

| Industrial Kitchen Type | Typical Scenario Description | Core Pain Points |

| Central Kitchen | Large-scale food processing centers for chain restaurants with complex pipeline networks and daily grease accumulation exceeding 50kg | Grease buildup reduces exhaust efficiency by 40%, requiring 12-hour manual shutdowns for cleaning, resulting in annual maintenance costs over ¥150,000 |

| Hotel Commercial Kitchen | Stove area pipelines (32cm diameter) with high-temperature grease in fire-prone zones | Fire hazards during manual cleaning necessitate gas equipment shutdowns, causing ¥20,000/day revenue losses; 3m-high pipeline climbing risks falls |

| Food Processing Plant | Dedicated pipelines for boiling/v frying lines with protein/starch residues prone to bacterial growth | Microbial contamination risks FDA non-compliance; chemical cleaning corrodes stainless steel pipelines, costing ¥80,000/year in replacements |

| Commercial Complex | Shared main exhaust ducts serving 30+ vendors, leading to cross-contamination | Traditional methods fail to clean bends/variable diameters (coverage <60%), risking environmental compliance failures |

| Hotpot/BBQ Establishment | Pipeline interiors with 2cm-thick carbon deposits from high-temperature fumes and open flames | Extreme fire risks; manual cleaning requires gas masks and 8-hour operations |

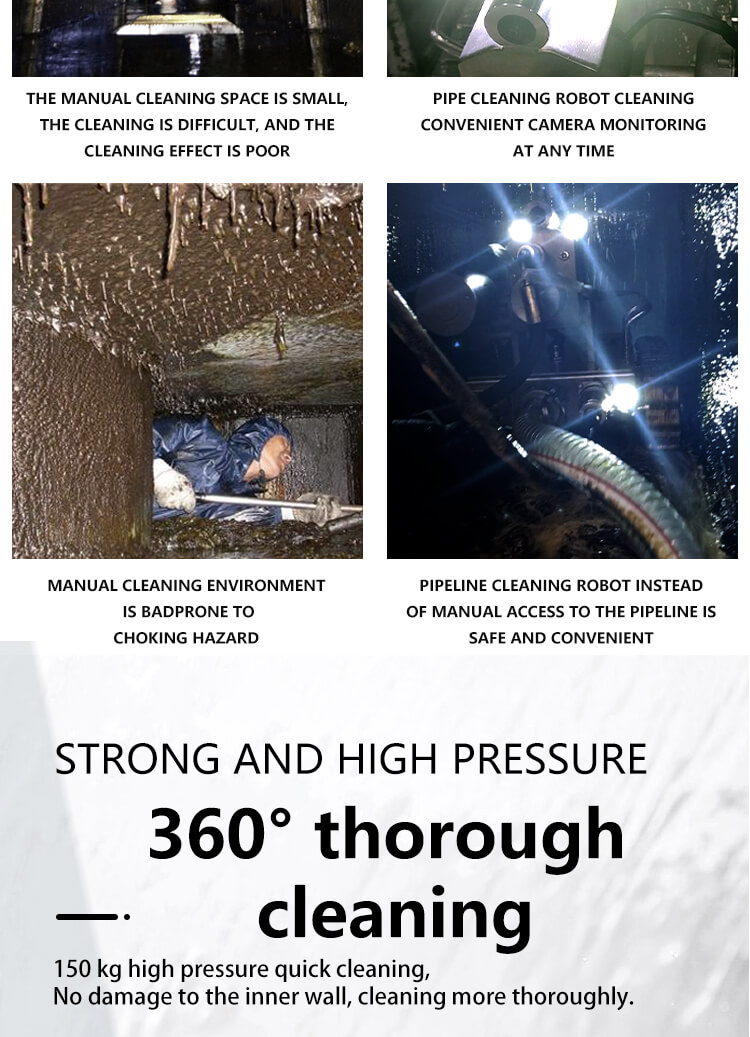

Comparison: Manual vs. Robotic Cleaning

| Comparison Dimension | Manual Cleaning | Robotic Cleaning |

| Operational Efficiency | Requires 3-5-person teams, 6-8 hours per session | Single-operator control, 3 hours for complex pipelines (300% efficiency improvement) |

| Safety Risks | 3% annual accident rate (oil suffocation, chemical burns) | Remote-controlled zero-contact operations; 98% risk reduction through hazard avoidance design |

| Cleaning Quality | Residual grease >5g/m²; 40% microbial contamination rate | 360° rotating brushes + vacuum system (<0.5g/m² residual; FDA-compliant) |

| Cost Structure | ¥8,000/month (labor) + ¥3,000/month (consumables) | 75% cost reduction per session via automation |

Functional Modules, Technical Specifications, and Application Value

| Functional Module | Technical Specifications | Application Value |

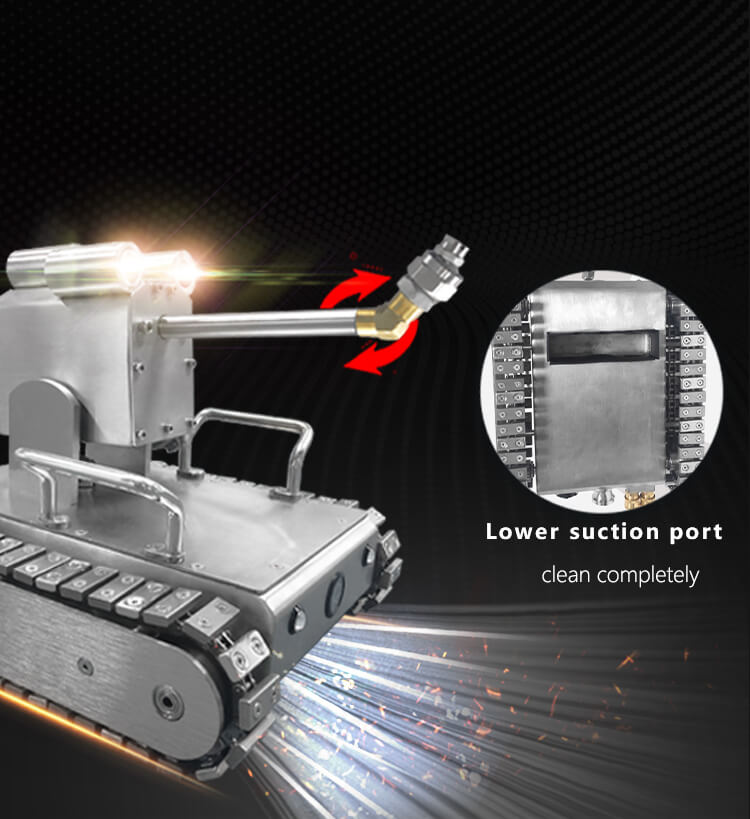

| 360° Rotating Cleaning System | - Nozzle with four adjustable angles (0°, 15°, 25°, 40°) - Compatible with high-pressure, high-temperature machinery (e.g., P33) providing 2900psi water pressure | Eliminates single-side scrubbing limitations, adapts to diverse grease-accumulated pipelines, and removes >95% wall deposits |

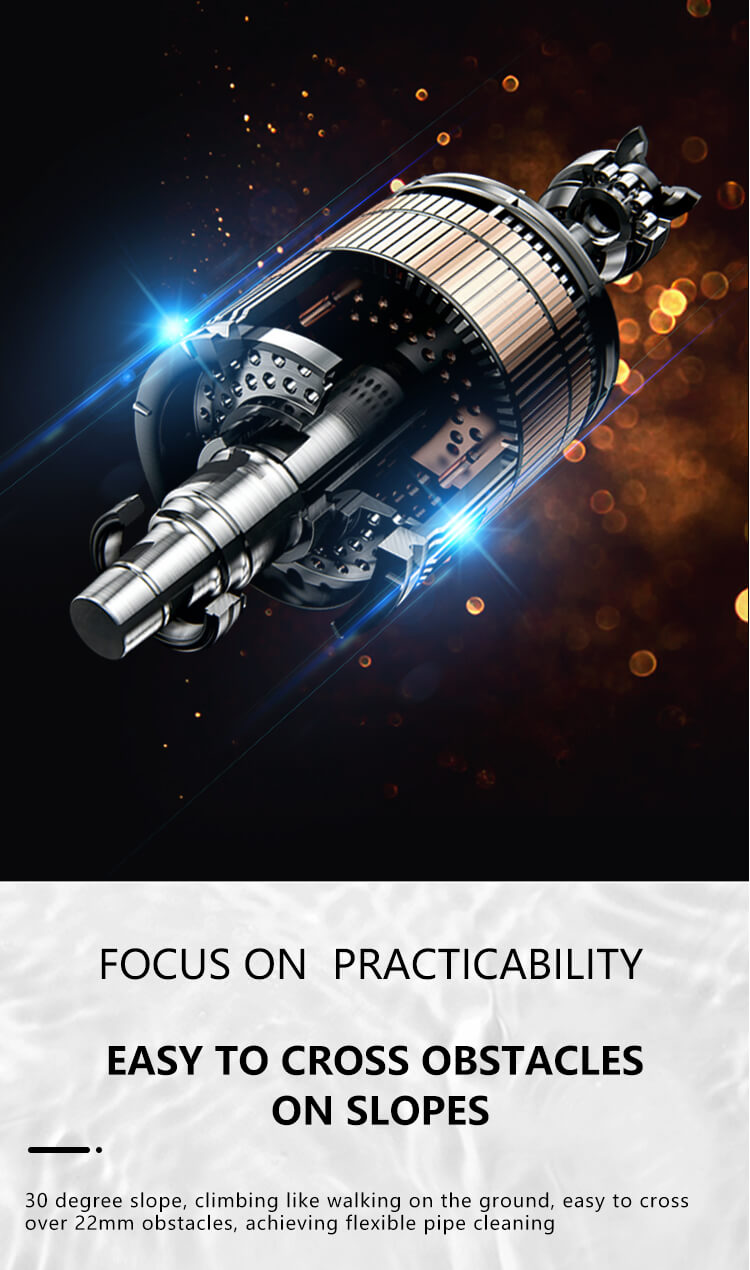

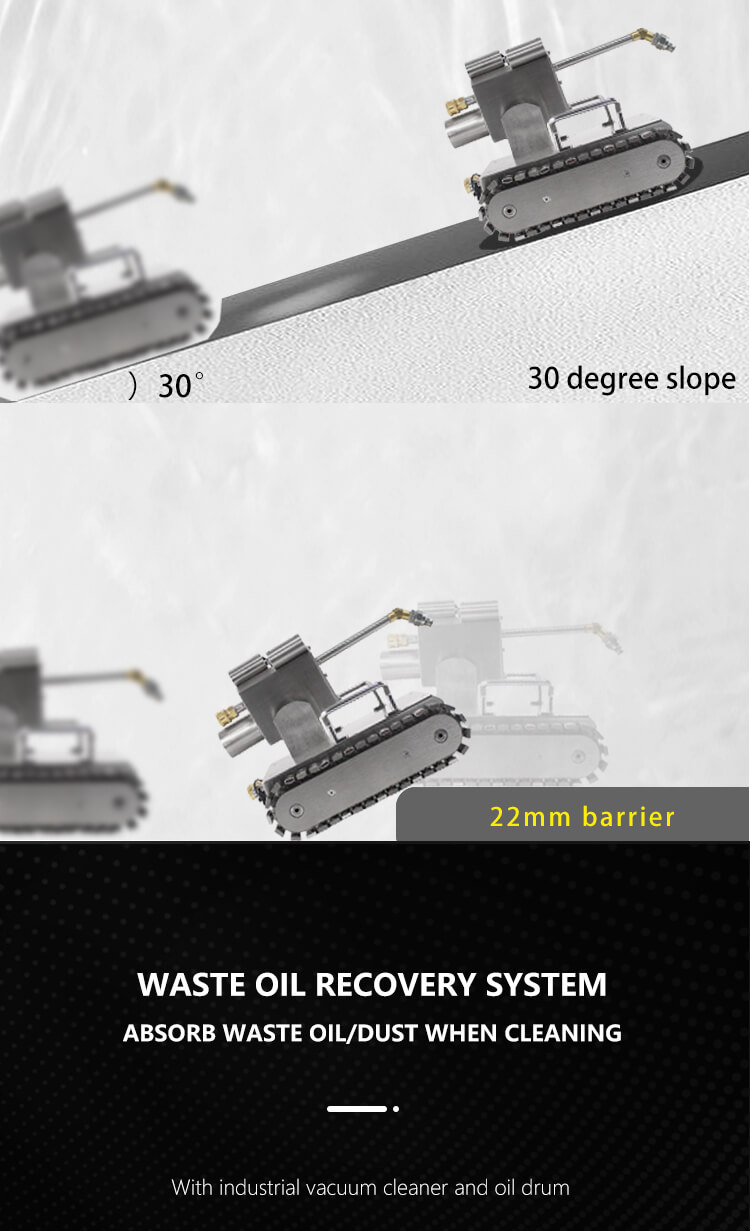

| Slope Climbing | - Magnetic crawler system - Max. 30° slope climbing capability | Navigates complex terrains (e.g., kitchen ceiling interlayers), addressing inaccessible dead zones for manual cleaning |

| Obstacle Clearance | - Clearance height: 22mm | Avoids destructive pipeline cutting, protecting high-value alloy pipelines (cost: ¥200,000/meter) |

| Vacuum Oil Recovery System | - Oil absorption efficiency: 98% - Waste oil recovery rate: >90% | Reduces hazardous waste disposal by 15kg per session, lowering environmental compliance costs |

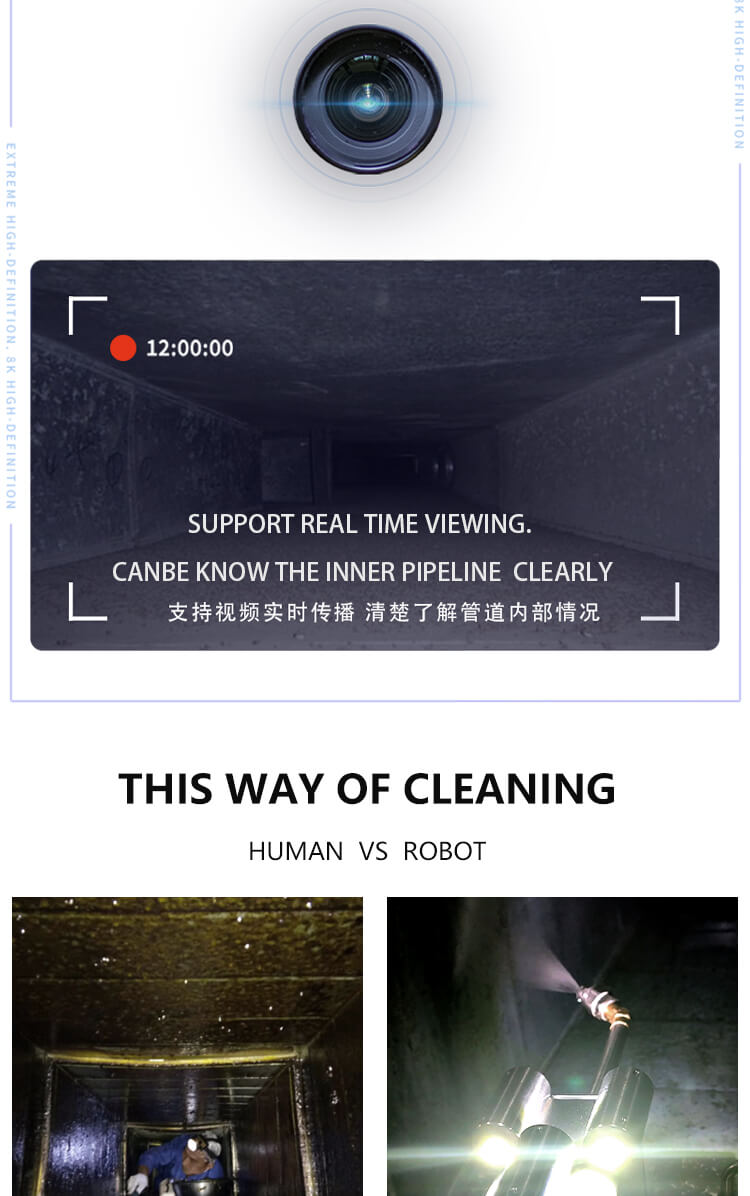

| HD Imaging System | - 1080P wide-angle camera - 4K video recording | Achieves >95% defect detection accuracy, replacing traditional endoscopes or blind manual inspections |

FAQ: High-Pressure Water Cleaning vs. Steel Brush Cleaning

1. What is the difference between high-pressure water cleaning and steel brush cleaning?

High-pressure water cleaning achieves a removal rate of over 95% for hard deposits (e.g., water scale, grease sludge), and excels at cleaning pipeline dead zones and complex structures. Steel brush cleaning performs well on flat metal stains but struggles to address dirt in crevices or deep holes, and may cause residue due to uneven friction. Additionally, steel brushes are prone to causing scratches on soft coatings (e.g., aluminum-plated layers).

2. Can high-pressure water cleaning achieve thorough cleaning?

The robot, when paired with a high-temperature high-pressure water machine (e.g., P33), can spray high-pressure hot water at 2900 psi and 90°C for cleaning. For stubborn grease, it can be combined with a P24 chemical spray machine to pre-soften the grease prior to cleaning, achieving better cleaning results.