Urban pipelines are responsible for critical functions such as sewage discharge, rainwater transportation, and gas supply. However, because they are buried underground for a long time, these pipelines are often neglected until serious accidents occur.

The U.S. Environmental Protection Agency (EPA) 2022 Clean Watersheds Needs Survey (CWNS)indicates that approximately $630 billion will be required over the next two decades (2022–2041) to address aging sewer systems in the United States, with sanitary sewer overflows (SSOs) and related repair costs accounting for a significant proportion of these investments

The root of these problems lies in the fact that traditional manual inspections rely on experience for judgment, are inefficient, high-risk, and it is difficult to fully grasp the internal conditions of the pipelines.

To solve the limitations of traditional inspection methods, the new K22 pipeline inspection robot has emerged. It is designed for municipal sewage pipes, stormwater drains, industrial pipelines, and underground utility tunnels. It can achieve precise, efficient, and non-destructive internal inspections without excavation.

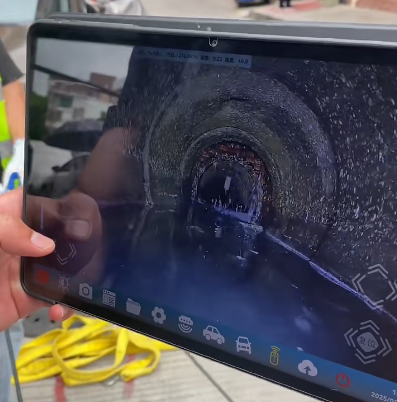

High-definition touch tablet, wireless remote control: Equipped with a high-definition touch tablet, it supports wireless connection. Operators can remotely control the robot from a safe distance through the tablet to move forward, backward, hover, and make fine adjustments to ensure the robot can reach any designated position inside the pipeline for detailed inspections. The operation interface is designed to be intuitive and easy to understand, so that even novice operators can quickly get started, greatly reducing the learning threshold and training costs.

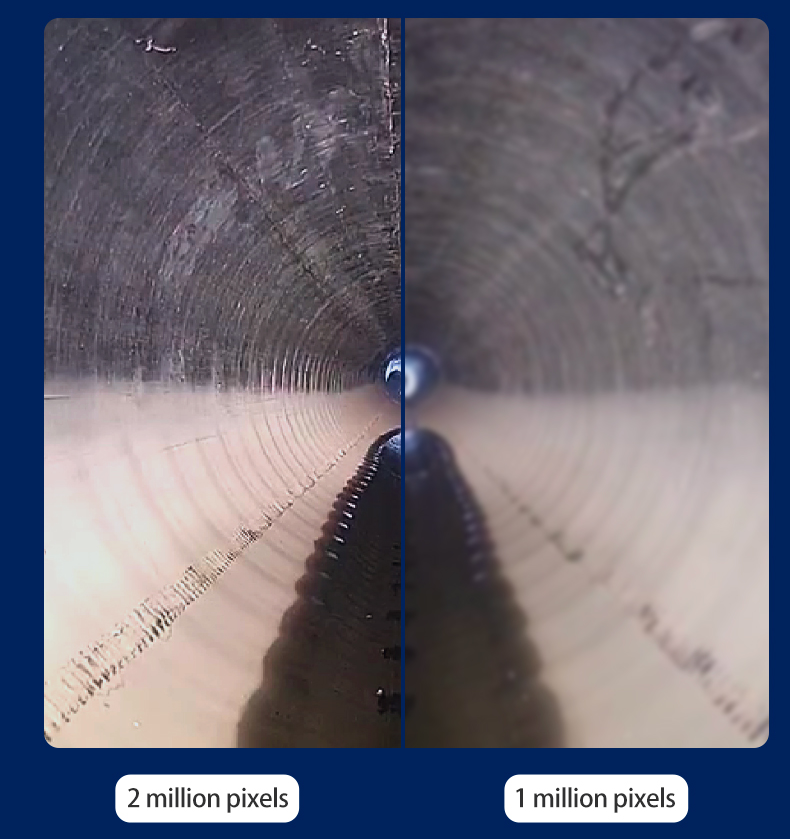

1080P real-time video transmission, clear picture quality: Equipped with a 2MP high-definition camera, it can provide 1080P full high-definition real-time video transmission, with clear pictures and high color reproduction, and can capture extremely subtle changes inside the pipeline. Paired with high-brightness and adjustable LED fill lights, even in extremely dark environments (such as pipelines buried deep underground for several meters and without natural light) or turbid water quality (such as heavily polluted sewage pipelines containing a large amount of silt, grease, and debris), it can also clearly identify tiny cracks with a width of only 0.1 mm, early rust spots, and small sediment particles and other defects to ensure the accuracy and reliability of the inspection results.

360° horizontal rotation, all-round scanning without dead angles: The camera supports free 360° horizontal rotation, which can all-round and without dead angle scan the inner wall of the pipeline. Whether it is the top, bottom or side wall of the pipeline, it can be carefully inspected to ensure that no potentially problematic areas are missed. During the rotation process, the robot can maintain a stable shooting state and provide smooth and coherent video pictures, which is convenient for operators to comprehensively understand the overall condition of the inner wall of the pipeline.

One-click lifting adjustment, flexible adaptation to different pipe diameters: Equipped with an advanced electric lifting system, it supports the one-click lifting adjustment function. Operators can easily adjust the height of the camera through simple operations on the tablet. When encountering a pipeline with a smaller diameter, the camera can be adjusted to a suitable height to shoot close-up pictures, clearly capturing details such as crack width, corrosion depth, and local damage; in a pipeline with a larger diameter, the camera can be raised to scan the overall pipeline structure from a more macroscopic perspective, observing trends in pipeline deformation and the distribution of large-area sediments, etc., to achieve comprehensive inspection of problems in different parts and at different scales of the pipeline.

4. IP68 Waterproof, Adapt to Extreme Environments

IP68 top-level protection certification, fearless of harsh conditions: The whole robot has passed the international standard IP68 protection certification, which means it has excellent completely dust-proof and waterproof performance and can work stably underwater for a long time. Whether in sewage pipelines with long-term high water levels, drainage channels with extremely high groundwater levels and rapid water flow, or complex industrial pipeline environments full of slurry and chemically corrosive liquids, the robot can maintain stable performance and ensure the smooth progress of the inspection work. Its sealing structure uses high-strength and corrosion-resistant special materials, effectively preventing moisture, dust, chemicals, etc. from eroding the internal precision electronic components and mechanical parts, greatly extending the service life of the robot and reducing maintenance costs.

Full high-definition video recording, no omissions of key information: The robot is equipped with a large-capacity high-speed storage device, which can automatically and continuously record the 1080P high-definition video of the entire inspection process, completely recording every detail and change inside the pipeline. During the inspection process, operators can manually mark and annotate specific abnormal situations as needed, which is convenient for subsequent viewing and analysis. These records not only provide detailed data support for the current inspection work, but also provide valuable historical data for subsequent pipeline maintenance, renovation, and management.

One-click screenshot, accurate problem positioning: When operators find abnormal situations (such as cracks, leakage points, root intrusions, etc.) in the video, they only need to click the "screenshot" button on the tablet lightly, and they can instantly capture and save high-resolution abnormal pictures, accurately locking the specific location and status of the problem. These screenshots can be used as important evidence and reference materials for subsequent maintenance plan formulation, liability determination, etc., greatly improving the efficiency and accuracy of problem handling.

Contact Us: WhatsApp +86 17898458979 | E-mail: sales@rj-bot.com