According to the 2024 China Commercial Kitchen Equipment Management White Paper, 83% of chain catering enterprises incur additional annual cleaning and maintenance costs ranging from RMB 50,000 to 200,000 due to pipeline blockages and grease accumulation. Traditional cleaning methods generally trade manpower and resources for nothing more than temporary unblocking. What industrial kitchen grease pipelines truly require is not just an emergency response plan, but a scientific, long-term, and safe cleaning system. The selection of industrial kitchen grease duct cleaning equipment directly impacts kitchen safety, operational costs, and long-term efficiency. In today’s market, similar products vary significantly in functionality. This article will conduct a horizontal comparison of these solutions, integrating field-tested data and user feedback to help you identify the option that best aligns with your operational needs.

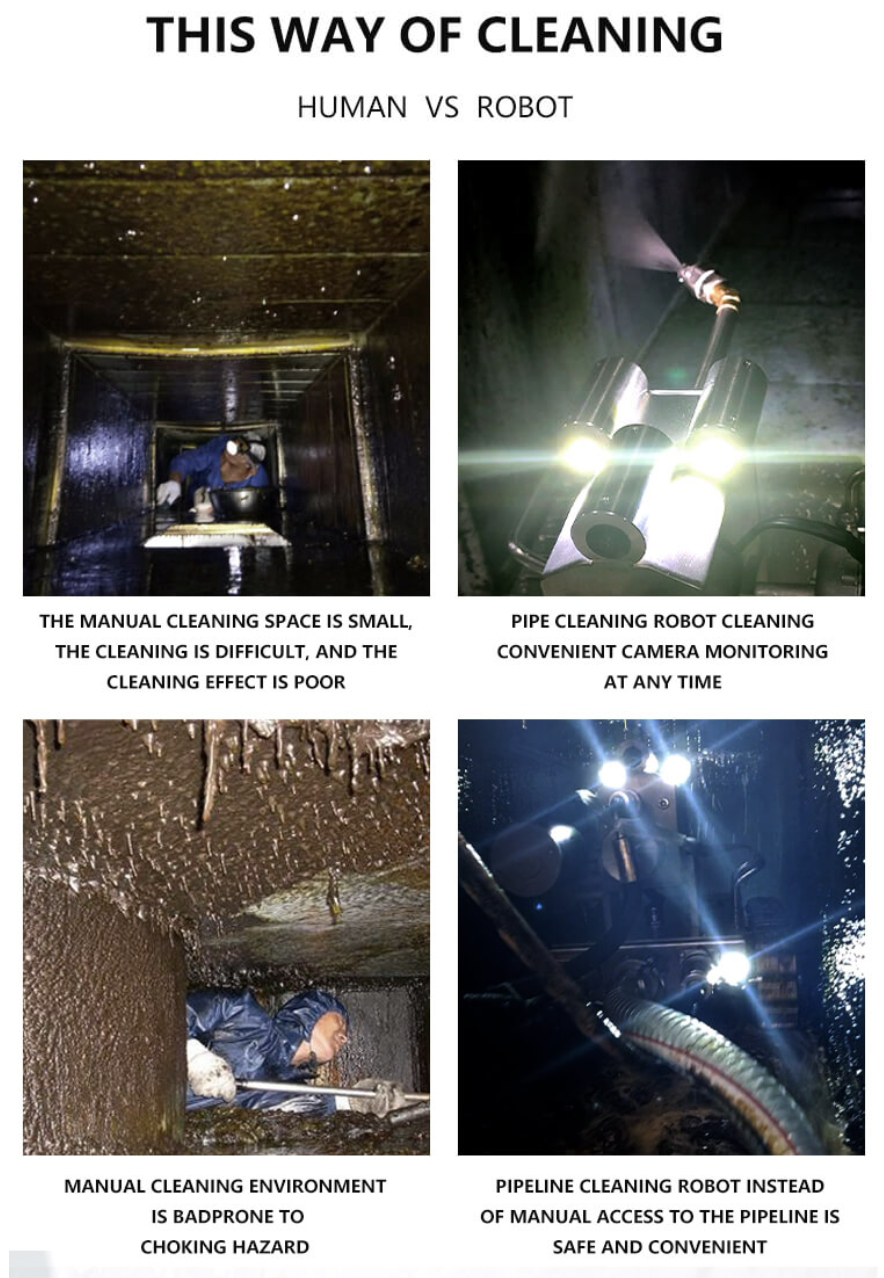

II. G36 Industrial Kitchen Grease Duct Cleaning Robot VS Traditional Manual Cleaning Equipment

1. No Camera Monitoring: "Blind" Cleaning Leads to High Miss Rate

Traditional manual tools rely on operators’ visual judgment and experience to assess cleaning effectiveness. However, due to dim lighting and complex structures inside pipes, observation coverage is limited to just 40%-50%.

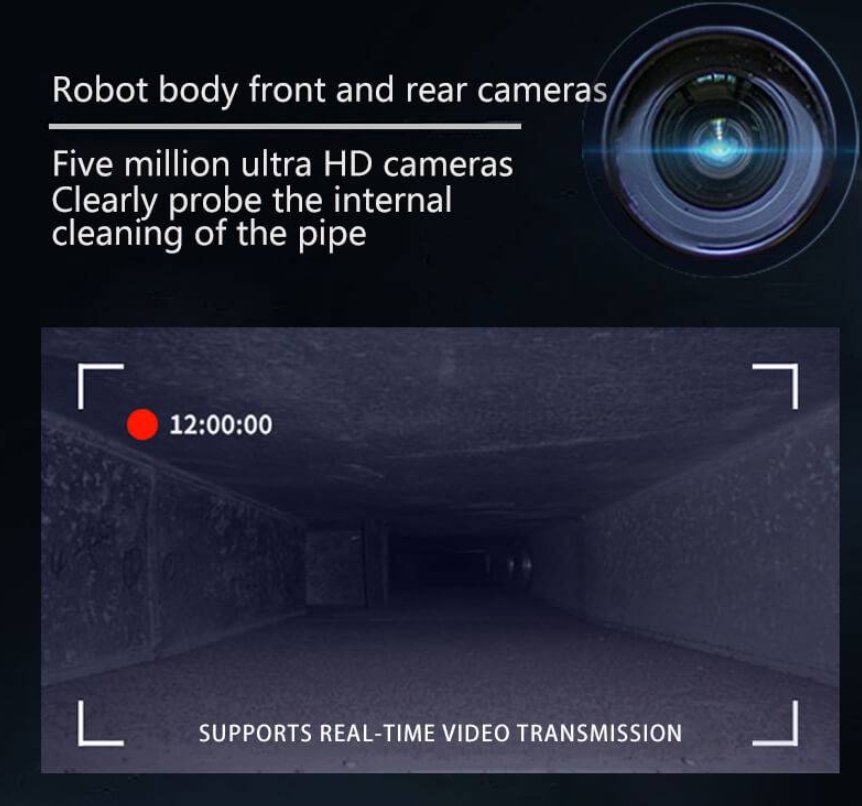

In contrast, the industrial robot is equipped with a 4K HD camera and LED lights, enabling 100% real-time visibility of pipe interiors. Operators can directly observe grease distribution via the display, adjust cleaning strategies, and eliminate guesswork in cleaning entirely.

2. Limited Length: Frequent Segmentation Wastes Time and Resources

Traditional tools are constrained by pipe connectivity and mobility. For large kitchens or central kitchens with total pipe lengths exceeding 50 meters, this requires 3-4 segmented cleanings, increasing total time by 40%.

The robot uses a modular track and wheel design, supporting continuous cleaning up to 25 meters. Paired with intelligent path planning, it completes full-pipe coverage in one pass.

III. Scientific Perspective: Why G36 Is More Durable and Efficient

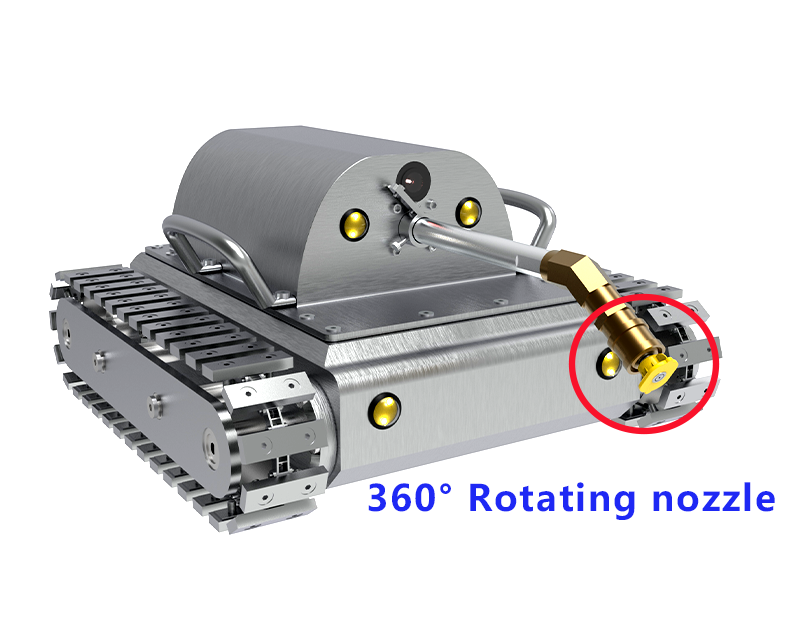

1. 360° Rotating Nozzle: Eliminating Cleaning Blind Spots Through Precision Engineering

Traditional cleaning robots often rely on fixed-angle or limited-swing nozzles—a design that severely limits their effectiveness in complex pipeline systems. Fixed nozzles, constrained by their static orientation, cannot adjust to these curves or transitions. As a result, high-pressure water jets fail to reach the inner walls of bends, the recessed edges of tees, or the "dead zones" behind debris clusters. Over time, this leads to persistent oil, grease, and sludge accumulation—problems that not only compromise pipeline functionality but also create hygiene hazards or fire risks

Our G36 robot redefines pipeline cleaning with its 360° rotating nozzle, a breakthrough engineered to eliminate these blind spots entirely. The nozzle is powered by a high-torque, brushless micro-motor that enables smooth, consistent rotation at adjustable speeds. Even in harsh environments,the rotation of the nozzle is perfectly synchronized with the robot’s forward movement and the high-pressure water jet’s output. Even in the tightest bends, where fixed nozzles would skid past.III.

2. 95°C Constant-Temperature Hot Water: Deeply Softening Aged Grease

The aging process of grease is fundamentally an oxidative polymerization reaction. The melting point of this aged grease rises significantly from 30-40°C in fresh grease to 50-70°C, meaning 85°C water used by most traditional devices struggles to surpass its solidification threshold.

Our robot stabilizes water temperature within a "golden range" of 95°C. 95°C thermal energy effectively disrupts the molecular cross-linked structure of aged grease. Experimental data show that after 10 seconds of contact with 95°C hot water, the surface molecular movement rate of aged grease increases by 42% compared to 85°C water, achieving full softening in just 30 seconds (whereas 85°C water requires over 2 minutes).

Paired with our robot’s two-stage suction system, the liquefied grease is directly drawn into a sealed collection tank, completely eliminating issues of grease dripping or re-adhesion during cleaning. This truly delivers on the promise of "one-pass cleaning, long-term compliance."

3. Separate Detergent and Cleaning Pipes: Avoiding Corrosive Cleaning and Extending Machine Life

Some peer products simplify operations with a detergent-cleaning combo design, where chemical cleaners and high-pressure water share the same pipe. While convenient, this design hides risks: residual chemicals corrode internal metal components, increasing failure rates by over 30%.

Our robot adopts a dual independent piping system: the detergent pipe only delivers cleaner, while the cleaning pipe focuses on high-pressure water. This separation prevents chemical residues from corroding the machine. Our design extends equipment lifespan by 2-3 years compared to combo models.

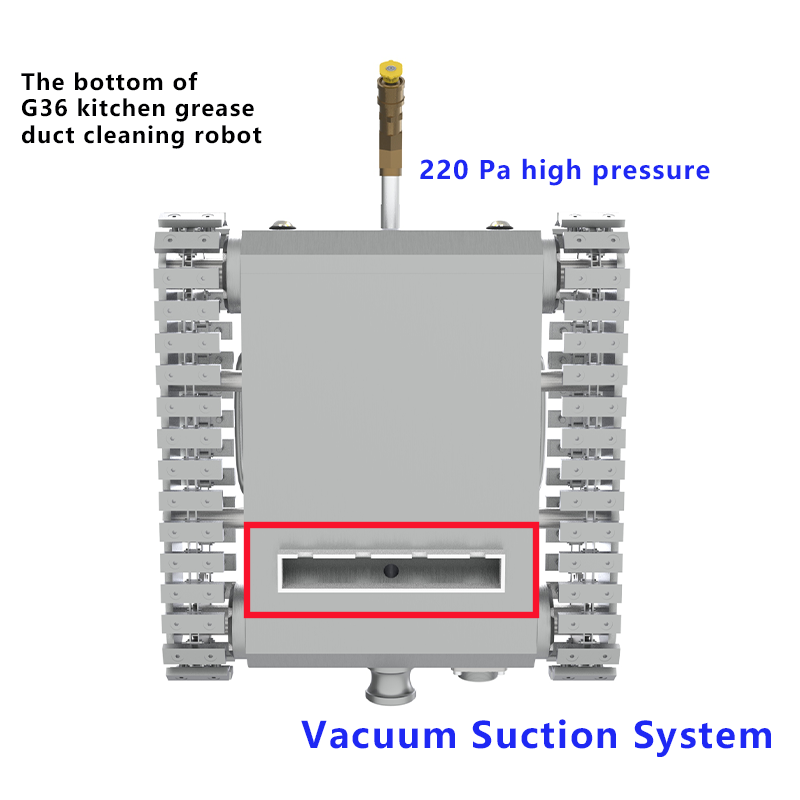

4. 200Pa High Pressure + 2-Level Suction: "Wash + Suck" Synergy to Eliminate Residue

Unlike traditional systems limited to ≤160Pa, our robot is equipped with a robust 200Pa high-pressure pump. This elevated pressure delivers targeted, high-velocity water jets capable of dislodging even hardened grease, oil, and food particulates embedded in surfaces—whether it’s kitchen tiles, factory floors, or commercial cooking equipment. The precision-engineered nozzle array ensures uniform coverage, preventing streaks or missed spots, even on irregular or hard-to-reach areas. Complementing the high-pressure system is a dual-stage suction mechanism with adjustable intensity. This feature addresses a critical gap in traditional designs: while high pressure removes debris, it often scatters wastewater or leaves fine oil residues if extraction is weak or poorly timed. Our solution synchronizes the high-pressure jet with powerful suction, ensuring that grease and waste are immediately lifted from the surface and into the robot’s sealed collection tank—no splashing, no drips, no residual sludge.

5. IP65 Waterproofing and Intelligent Monitoring: "Dry Inside + Safe Operation" Synergy to Prevent Damage

The true environments of industrial kitchen pipelines present unique challenges, including constant humidity, splashes of water during cleaning, and the presence of standing water (such as in grease trap pipelines). These conditions significantly threaten the durability of cleaning devices. Many peer products claim "IP64 waterproofing," but this rating falls short in addressing the harsh, wet realities of industrial kitchens. IP64 creates two key vulnerabilities. Constant 80%-90% humidity in steam-heavy environments allows water vapor to seep through microscopic gaps in IP64-sealed enclosures, corroding internal circuits over time. Also, frequent water splashes during cleaning can pool on joints or vents, exceeding IP64’s "short-term spray" protection and leading to gradual water ingress.

Our robot is certified to IP65. This isn’t just a higher number but a design revolution for wet industrial environments. Even during high-pressure cleaning, the robot’s sealed ports and elevated motor placement prevent water from reaching critical electronics.

IV. From "Invisible Risks" to "Visible Peace of Mind"

Industrial kitchen grease pipelines are not simply "stubborn nuisances"; they are essential components of effective scientific management. The G36 Robot utilizes advanced technologies, such as "thermal melting and high-pressure rotary spraying," along with an IP65-rated waterproof design. This combination addresses durability challenges in humid environments. After all, truly smart equipment must not only function effectively but also withstand the test of time.