During the daily operation of industrial kitchens, a large amount of high - temperature cooking oil, steam, and food residues are produced. These substances continuously accumulate in the pipelines, easily forming stubborn layers of grease deposits, which lead to the massive reproduction of pathogenic bacteria.

For catering enterprises, whether they can effectively solve the pipeline cleaning problem is directly related to their legal and compliant operation. From China to Europe and the United States, from Asia to Australia, countries have introduced strict laws, regulations, and regulatory requirements. If enterprises fail to meet the cleaning compliance requirements, they will face a series of serious consequences such as fines, suspension of business for rectification, and damage to their reputation, and may even affect their survival and development.

Faced with the cleaning needs of greasy pipelines, the global catering industry has long relied on the traditional manual cleaning mode. However, this mode is facing three fatal defects of "inefficiency, difficult to meet standards, and high risks", which form a sharp contradiction with the increasingly strict global regulatory requirements.

Reliance on manual scraping, flushing, or chemical soaking means that the cleaning intensity, frequency, and coverage range vary greatly depending on the workers' experience and sense of responsibility. Hidden areas such as elbows and tees are often overlooked. Stubborn grease deposits are merely pushed aside rather than completely removed and will re - accumulate within weeks, failing to meet compliance requirements.

Manual cleaning requires the shutdown of operations after the peak dining hours, which affects the normal business of catering enterprises. At least 2 - 3 people are needed for a single cleaning operation, and complex pipelines take 2 - 4 hours to clean. For chain catering enterprises, the annual cleaning cost for stores across the country amounts to millions of yuan. For small and medium - sized catering stores, the high labor cost of 300 - 800 yuan per cleaning session squeezes their profit margins. Moreover, the manual mode can hardly meet the high - frequency regulatory requirements, making it impossible to achieve "timely and continuous" compliance.

Workers face multiple dangers when cleaning inside pipelines. Firstly, there is a risk of scalding from high temperatures, as the residual steam in the pipelines can reach 80 - 100°C, and workers are prone to scalding during operation. Secondly, there is a risk of slipping and falling on the oily and slippery ground, especially when working on the top of pipelines. Thirdly, there is a risk of inhaling toxic gases, as decaying grease volatilizes harmful gases such as hydrogen sulfide and methane. Long - term exposure to these gases can lead to respiratory diseases and other health problems.

These safety accidents not only bring physical pain and economic losses to workers but also expose catering enterprises to legal risks and reputational damage.

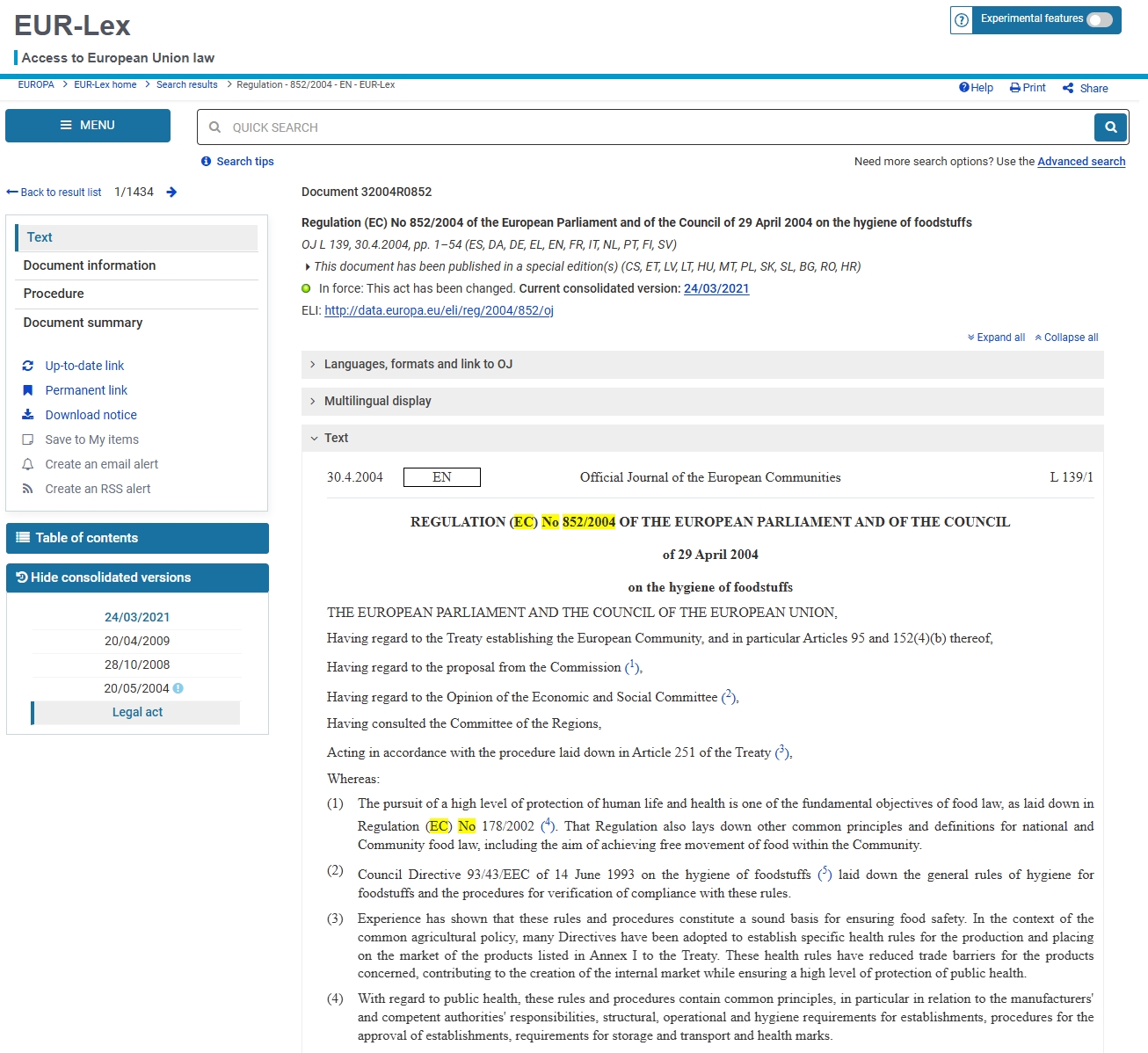

The EU Food Hygiene Regulation (EC No 852/2004) requires that the "drainage systems and ventilation ducts in all food processing premises (including kitchens) should be kept free of grease, odors, and harmful organisms". The detailed standards of member states stipulate that the grease residue in commercial kitchen exhaust ducts must not exceed 50 mg/cm² (detected by professional instruments), otherwise it will be regarded as "not meeting hygiene standards". The German Occupational Safety and Health Actemphasizes that workers entering pipelines for cleaning must meet the "confined - space work safety standards" (such as mandatory ventilation and fall - protection measures), which indirectly increases the cost of manual cleaning and prompts enterprises to turn to automated solutions.

The FDA Food Code requires catering establishments to "Food establishments shall clean all food - contact surfaces and associated equipment (including drainage systems and exhaust ducts) to prevent contamination and pest harborage. Grease accumulation in exhaust systems shall be controlled to prevent fire hazards.". More importantly, the US National Fire Protection Association (NFPA) has a mandatory regulation that commercial kitchen exhaust ducts must be "cleaned once a quarter, and a grease accumulation thickness exceeding 1/8 inch (about 3 mm) is regarded as a fire hazard". Violations may lead to insurance companies refusing to provide coverage or high - amount fines (the compensation for a single accident can reach millions of dollars).

<img src="https://rjbotimg.rongjiang8.com/0ue175680400893.jpg" title="The FDA Food Code in United States.jpg" alt="The FDA Food Code requires catering establishments to "Food establishments shall clean all food - contact surfaces and associated equipment (including drainage systems and exhaust ducts) to prevent contamination and pest harborage.jpg" width="994" height="464" style="width: 994px; height: 464px;"/>

The Japanese Food Sanitation Lawstipulates that kitchen drainage pipes should be "checked for unobstructedness daily and cleaned for oil - stained attachments weekly", and the cleaning records must be kept for at least two years. The National Environment Agency (NEA) of Singapore implements a "catering hygiene rating system" (A - D grades) for catering enterprises. If the pipeline cleaning does not meet the standards, the enterprise will be directly downgraded, which will affect its customer traffic and business license.

Against this backdrop, if catering enterprises still rely on the traditional manual cleaning mode, they will not only find it difficult to meet the compliance requirements (facing fines, suspension of business, and reputational losses) but may also pay a heavy price for safety accidents. The "unsustainability" of the traditional mode and the "mandatory" nature of global regulations create a strong conflict, forcing the industry to seek more efficient, safer, and more compliant solutions. This is the fundamental driving force behind the rise of industrial kitchen pipeline cleaning robots, which bring new hope and possibilities for solving the difficult problem of industrial kitchen pipeline cleaning.