For a long time, the robotics industry has been fascinated with the concept of humanoid robots. While the idea of robots mimicking human appearance and movements aligns well with science fiction, an increasing number of people are realizing that it may not be the optimal solution to real-world automation challenges. The form of robots should be defined by functional requirements and techno-economic feasibility. Blind pursuit of human-like designs risks deviating from the essence of technology. The development of new productive forces and the transformation of intelligent manufacturing do not rely solely on humanoid robots. As the saying goes, “A single flower does not make spring; a hundred blossoms bring spring to the garden.” The widespread application of diverse robots across industries is the key to driving the transformation and upgrading of industrial manufacturing.

The “Non-Human” Evolution

The future form of robots will be determined by functional needs, scenario adaptability, and techno-economic viability. Humanoid designs are by no means the only answer. Take warehouse and logistics operations as an example: the primary goals are moving large quantities of pallets, navigating narrow spaces, and optimizing throughput. Here, efficiency must take precedence over anthropomorphism. In nature, evolution shapes life forms to achieve optimal survival in their environments—birds evolve for flight, cheetahs for speed. Similarly, humans have developed airplanes, submarines, and cars based on bionic principles, optimizing them for specific tasks. Shouldn’t robot design follow the same logic, prioritizing functionality over familiarity? Robot design should solve problems in the most efficient way possible, free from constraints like mimicking human movement patterns.

In industrial manufacturing, complex challenges are rarely solved by humanoid robots. Solutions often lie in specialized robots designed to optimize motion, storage, and material flow. Non-humanoid robots—such as industrial robots, collaborative robots (cobots), and autonomous guided vehicles (AGVs)—have long been maturely applied on production lines. Their structural designs prioritize multi-axis freedom, high payloads, and precision. For instance, multi-axis robotic arms perform assembly tasks with millimeter-level accuracy, while AGVs transport goods 24/7 with far greater efficiency than humanoid counterparts. These robots prove that when form follows function, performance surpasses biomimetic designs. This underscores the core question in robotics: What is the most effective and reliable form for a specific task?

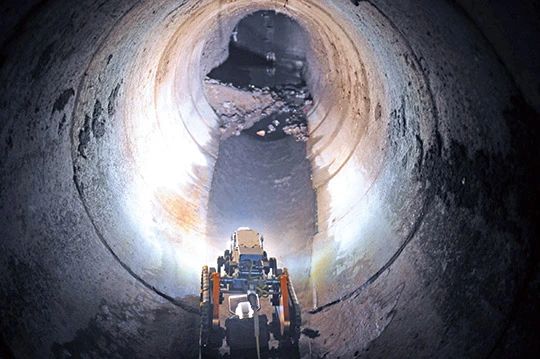

Consider municipal drainage pipeline inspection: avoiding road excavation and replacing manual labor are top priorities. In extreme environments, compact pipe inspection robots navigate narrow ducts, drones bypass terrain limitations with flight, snake-like robots penetrate rubble with flexible structures, and underwater robots conquer oceans with streamlined bodies. “Function determines form” is the iron law of robotic evolution. Forcing humanoid robots into such scenarios would be as clumsy as using human hands to replace cranes.

This explains why CCTV pipeline inspection robots, smart patrol robots, robotic arms, and retrieval systems have become industry standards over the decades—not bipedal robots attempting to imitate human labor.