The continuous tightening of policies is forcing catering enterprises to directly confront the compliance pressure of pipeline cleaning. Traditional manual cleaning methods, characterized by low efficiency, high risks, and difficulty in meeting standards, are gradually becoming ineffective. Enterprises urgently need to transform and seek better solutions. Intelligent cleaning robots, with their significant advantages of high efficiency, safety, and compliance, have emerged as a new choice for the global catering industry to address pipeline cleaning challenges.

Driven by policies, the proportion of catering enterprises in Europe, the United States, and the Asia-Pacific region purchasing cleaning robots has increased at an average annual rate of over 35% (data sourced from the MarketsandMarkets).

As an increasing number of enterprises turn to robots for kitchen duct cleaning, what criteria should we consider when selecting the right cleaning robots?

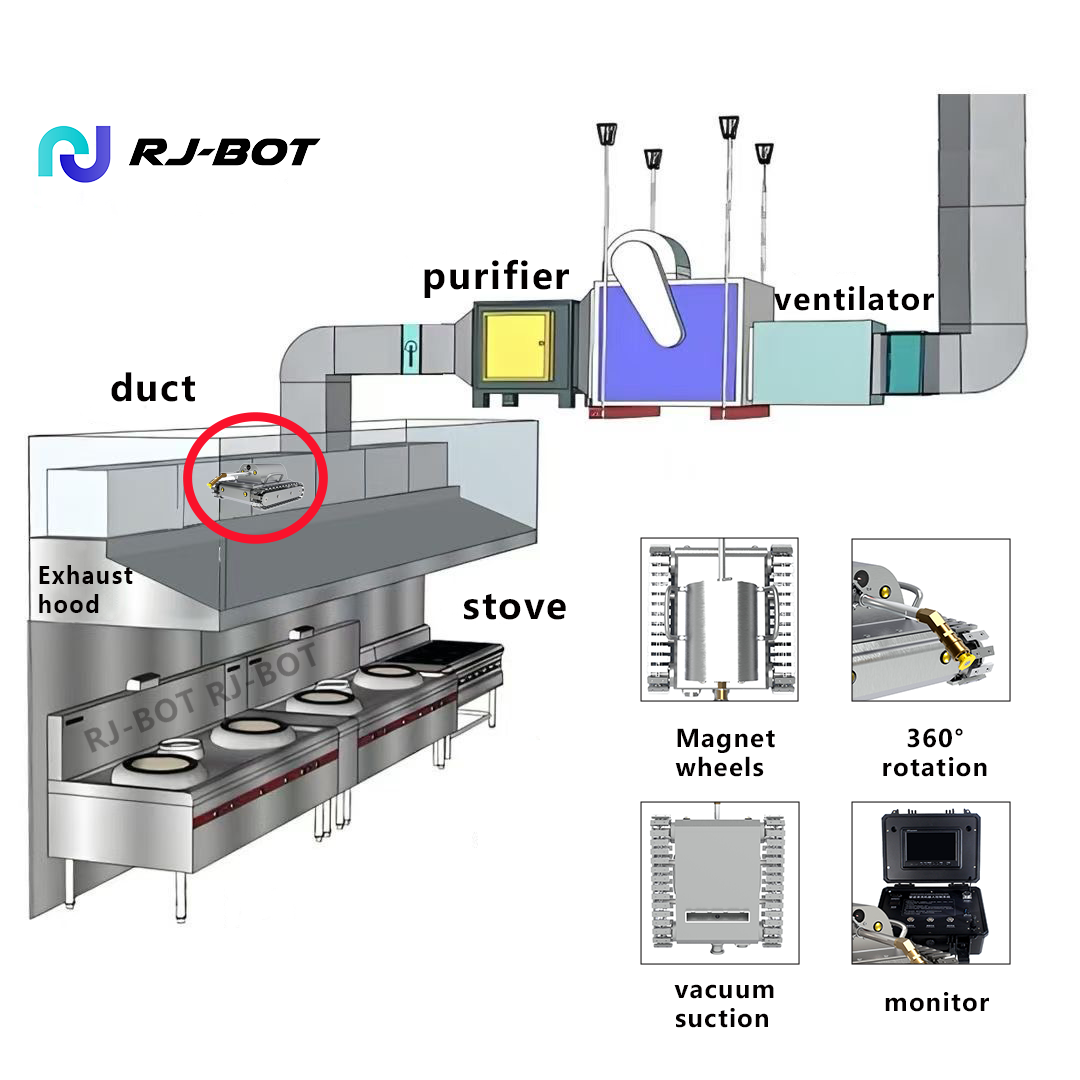

II. Technological Breakthrough: How G36 Cleaning Robots Meet Policy Requirements?

360° Rotating Nozzle: Precision Elimination of Cleaning Blind Spots

Traditional fixed nozzles struggle to reach curved and angled pipe sections, leaving behind stubborn grease buildup. The G36 robot features a high-torque, brushless micro-motor-powered 360° rotating nozzle that synchronizes seamlessly with its forward motion and water pressure. It delivers consistent coverage across bends, tees, and hidden zones, ensuring complete removal of persistent residues.

95°C Constant-Temperature Hot Water: Deep Breakdown of Aged Grease

Aged grease, with a melting point raised to 50–70°C, resists conventional 85°C cleaning. The robot maintains a precise 95°C "golden zone" temperature, accelerating molecular movement by 42% within 10 seconds and fully softening grease in just 30 seconds (vs. 2+ minutes with 85°C). Its dual-stage suction system instantly extracts liquefied grease, preventing drips or re-deposition for truly "one-pass, long-term compliance" cleaning.

Separate Detergent and Cleaning Pipes: Corrosion Prevention for Extended Lifespan

Rejecting the corrosion risks (30%+ higher failure rate) of combined detergent-water hoses, the robot employs a dual independent piping system—dedicated detergent delivery and focused high-pressure water flow. This separation eliminates chemical residue corrosion, extending equipment durability by 2–3 years versus mixed-pipe models.

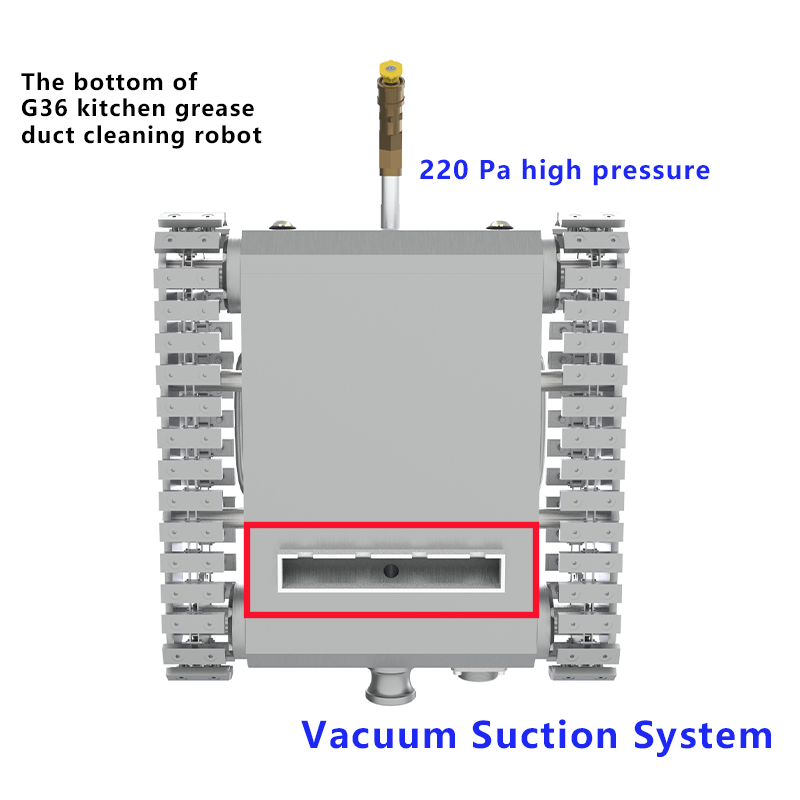

200Pa High Pressure + Dual-Stage Suction: Synchronized Wash-and-Suck for Zero Residue

Outperforming traditional systems (≤160Pa), the robot’s 200Pa high-pressure pump targets hardened grease, oils, and food particles on surfaces like tiles, floors, and equipment. Precision-engineered nozzles ensure even coverage, while adjustable dual-stage suction instantly removes dislodged debris. This synergy prevents splashing, drips, or residual sludge—no streaks, no misses, even on irregular surfaces.

IP65 Waterproofing & Intelligent Monitoring: Reliable Performance in Wet Environments

Industrial kitchen pipelines—constant humidity, cleaning splashes, and standing water (e.g., grease trap ducts)—challenge durability. While competitors claim IP64 (vulnerable to vapor seepage and splash ingress), the G36’s IP65 certification ensures sealed ports and elevated motor placement protect critical electronics. It operates flawlessly under high-pressure cleaning, preventing internal corrosion in harsh, wet conditions.

Policy Dimension: From "Bottom-Line Constraints" to "Benchmark Leadership"

The global regulatory framework is undergoing a transformation from "basic compliance" to "refined management." Future policies will exhibit three key trends:

Standardized Detection Methodologies:The EU may introduce unified protocols for grease residue testing (currently, countries rely on professional instruments with inconsistent standards).

Regularized Certification Systems: Clear thresholds will be defined for core parameters such as battery life, pressure accuracy, and grease removal rates.

Incentive Policy Advancement: Countries like Singapore and Japan may offer tax breaks (e.g., corporate income tax deductions), low-interest loans, or other subsidies to enterprises purchasing compliant robots, shifting the focus from "avoiding penalties" to "proactive technology upgrades."

These policy evolutions will drive the industry from "meeting minimum requirements" toward "pursuing optimal cleaning performance."

IV. Conclusion

Global policies are imposing increasingly stringent requirements on the cleaning of industrial kitchen pipelines—yet this precisely provides a vast stage for cleaning robots. They represent not only a technological innovation but also the optimal solution for enterprises to tackle compliance challenges and enhance operational efficiency.