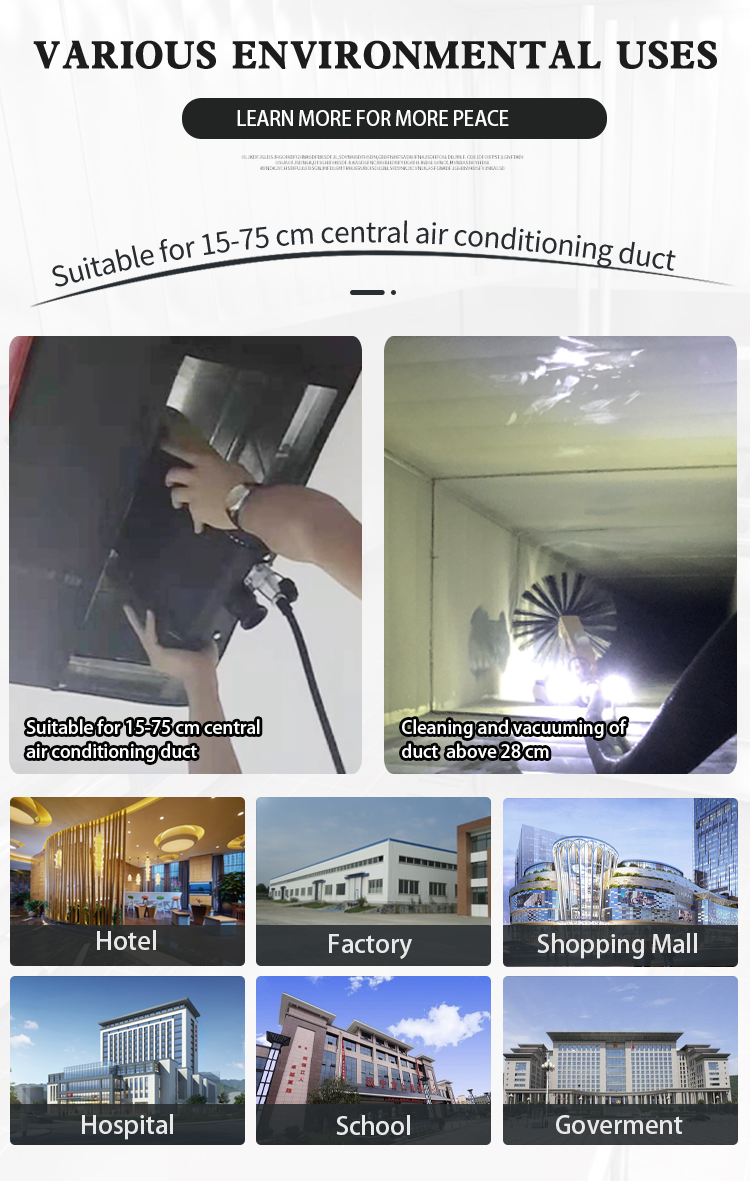

RJ-BOT, a leading player in China’s cleaning robotics industry, today unveiled its next-generation Q37 Air Duct Cleaning Robot. This cutting-edge product integrates visualized cleaning, high-speed nylon brush scrubbing, and a closed-loop dust recovery system, reducing operators' dust inhalation risk by over 90% during operation. It simultaneously enhances cleaning efficiency and safety, marking a new era of "precision cleaning + healthy operations" in the maintenance of commercial HVAC exhaust ducts. The Q37 is now open for orders from B2B clients, including hotels, office buildings, and hospitals.

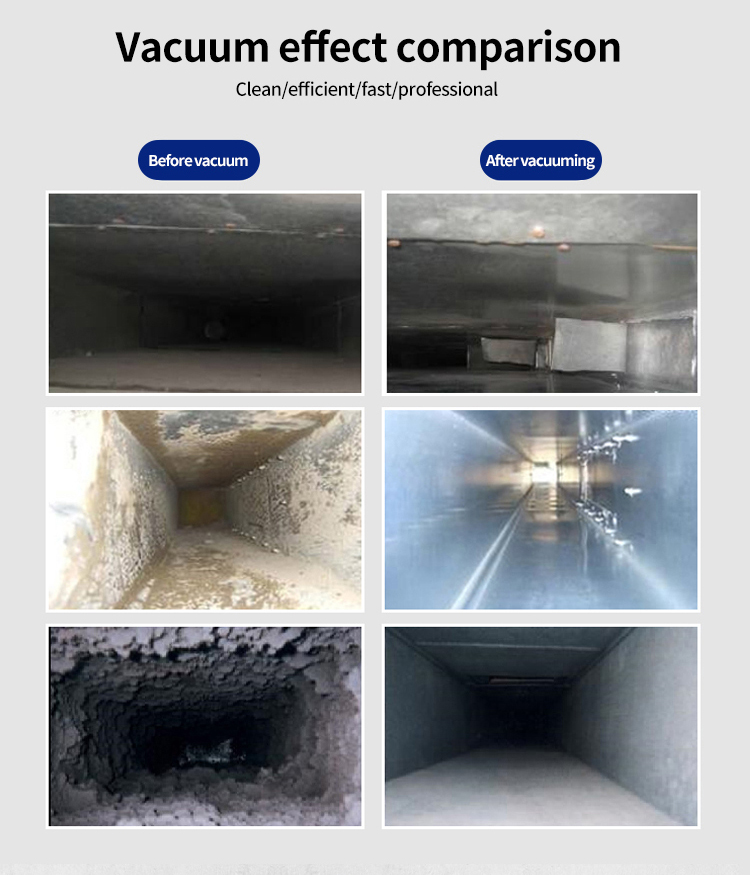

The Q37 Air Duct Cleaning Robot is an intelligent, specialized device designed for deep-cleaning narrow and high-risk spaces such as central air-conditioning ducts. Traditional manual cleaning methods—where workers physically enter ducts or rely on basic tools—often lead to issues like dust dispersion, limited visibility, and incomplete cleaning, posing long-term risks of respiratory diseases.

In contrast, the Q37 replaces human entry with robotic precision. Equipped with multi-sensor technology and a proprietary cleaning system, it enables fully unmanned, pinpoint-accurate, and safety-guaranteed operations. This ensures thorough duct sanitation while eliminating health hazards and inefficiencies associated with conventional methods.

II. Core Functions and Technological Breakthroughs

The new generation Q37 air duct cleaning robot features a patented quick change brush technology. It supports the rapid switching between single and double brushes within 3 minutes, easily handling the cleaning of 25 meter long ducts. The unique mechanical structure ensures full coverage cleaning of the entire duct without any dead zones, eliminating the need for manual re-entry and disassembly. It is also equipped with a 3 angle high definition infrared vision system (including front and rear cameras and a 120° wide angle lens), which can transmit high definition images inside the duct in real time. This system can accurately identify blockages, corrosion, and microbial growth, assisting in formulating targeted cleaning plans. The robot has a unique suck and scrub system. Its built in negative pressure suction port is directly connected to a vacuum device, which can immediately recover debris while the brush removes grease, mold, and particulate matter, avoiding secondary pollution. Moreover, it has outstanding mobility. Its rubber tracks can climb 30° slopes and cross 22 cm high obstacles, making it perfectly suitable for the bent pipes in hotel kitchens and complex ventilation networks in factories.

TECHNICAL SUPREMACY IN ACTION

Feature | Q37 Advantage | Standard Robots |

Obstacle Clearance | 22cm pipes/joists | <15cm |

Brush System | Interchangeable single/double heads | Fixed single brush |

Camera Resolution | Triple HD+IR with LED fill-light | Single low-res camera |

Suction Power | Integrated vacuum port | External unit required |

III. Why Is It Important? What Pain Points Does It Solve?

Air ducts serve as the "invisible pathways" of indoor air. Long-term accumulation of dust in uncleaned ducts can breed bacteria and mold (such as Legionellaand Aspergillus), which, when dispersed through airflow, may trigger respiratory infections, allergies, and other health issues. According to relevant studies, air-conditioning system pollution accounts for over 30% of indoor air pollution sources.

Traditional manual cleaning, however, relies heavily on experience. Workers are required to spend extended periods in high-dust environments, facing significant occupational health risks. Moreover, incomplete cleaning often leads to a "the more you clean, the dirtier it gets" vicious cycle.

The Q37 addresses these challenges by replacing manual labor with robotic technology. It not only protects operators by minimizing direct exposure to dust (eliminating high-risk environments) but also delivers "visible, thorough, and traceable" cleaning results through advanced technical solutions. This makes it particularly suitable for scenarios with stringent air-quality requirements, such as hospitals (preventing cross-infections), hotels (enhancing customer experience), and high-end residences (safeguarding family health).

IV. About the Company: Focused on Cleaning Robots, Driving Industry Upgrades Through Iterative Innovation

Founded in 2008, RJ-BOT is one of China’s earliest enterprises to specialize in the field of special-purpose cleaning robots. The company has long been committed to providing automated cleaning solutions for "high-risk, low-efficiency" scenarios. Its core team comprises experts from mechanical engineering, artificial intelligence, and environmental science. To date, RJ-BOT has launched a range of products—including the Kitchen Duct Cleaning Robot, X6 Livestock Manure Cleaning Robot, and K22 Pipeline Inspection Robot—accumulating 32 invention patents and 56 utility model patents.

In the air-duct cleaning segment, RJ-BOT introduced its first-generation cleaning robot (with basic vacuum functionality) as early as 2022. Through multiple iterative upgrades, the company has systematically addressed industry pain points such as poor duct adaptability, incomplete cleaning, and weak dust control. The newly launched Q37 represents its third-generation flagship product in this field, marking RJ-BOT’s transition from "functional implementation" to a comprehensive focus on "health + intelligence." This milestone further solidifies the company’s leading position in the niche market.

"Air cleaning is not just a surface task—it’s an 'invisible project' vital to respiratory health."

RJ-BOT aims to make the cleaning process safer, more efficient, and every breath of air cleaner. This is not only the product’s goal but also the company’s founding mission: to "protect healthy environments through technology."