Industrial-Grade Air Duct Cleaning Equipment for HVAC Systems

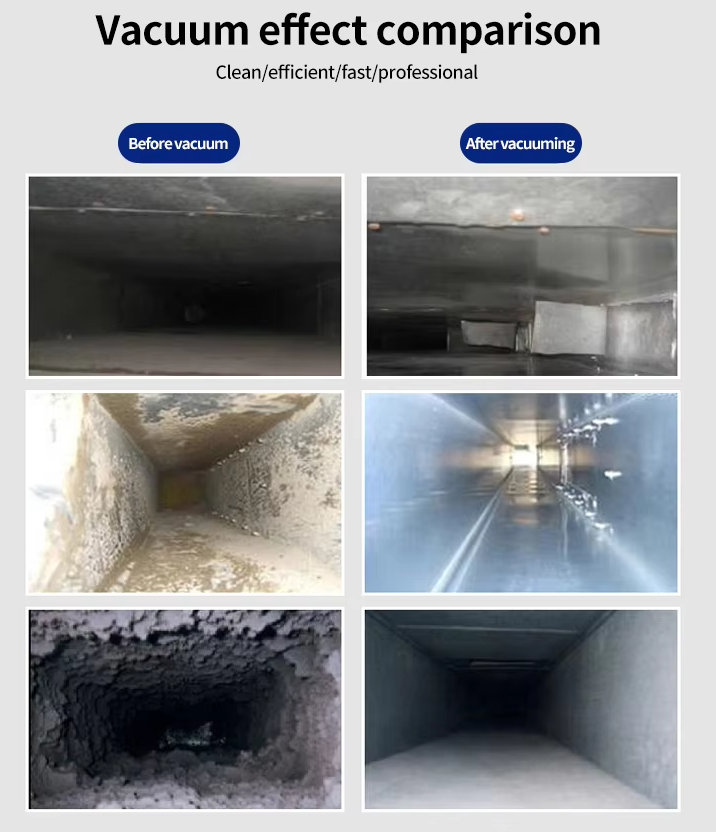

Revolutionize duct maintenance with the world's first modular robotic system. Engineered for 25-75cm commercial ducts, Q37 combines triple-camera inspection, dual-brush oscillation, and vacuum integration – achieving contaminant removal in a single pass.

Switch between single/double brushes in minutes for 25m pipes. No dead zones, no manual re-entry.

Front/rear cameras + 120° wide lens stream real-time video to diagnose blockages, corrosion, and microbial growth.

Built-in suction ports connect to negative pressure vacuum – capture debris while brushing.

Rubber tracks conquer 30° slopes & 22cm obstacles – critical for hotel kitchen bends and factory duct networks.

| Feature | Q37 Advantage | Standard Robots |

|---|---|---|

| Obstacle Clearance | 22cm pipes/joists | <15cm |

| Brush System | Interchangeable single/double heads | Fixed single brush |

| Camera Resolution | Triple HD+IR with LED fill-light | Single low-res camera |

| Suction Power | Integrated vacuum port | External unit required |

5-Star Hotels – Eliminate allergen buildup in HVAC without guest disruption

School Cafeterias – Meet grease extraction standards with video reports

Factory Canteens – Clear oil mist from 60cm exhaust ducts during night shifts

Government Facilities – Pass IAQ audits with video-cleaning certification

Hard nylon brushes dislodge grease, mold, and particulate matter.

Cameras detect hidden moisture and corrosion while LED lights map duct integrity.

Negative pressure suction captures 99.97% of PM0.3 contaminants via filters.

» Labor Savings: Clean 50m ducts in 30 mins vs. 4 hours manually

» Chemical Reduction: Dry process eliminates $380/month solvent costs

» Uptime Protection: Prevent 92% of duct-related HVAC failures

A: This robot uses a nylon material brush head, which is soft and will not cause scratches or damage.

A: The professional robot is equipped with a negative pressure dust collection system, which can suck dust and debris into the dust collection box while cleaning, preventing dust from spreading outside the pipes.

A: The robot is suitable for most central air conditioning ventilation duct systems, such as supply/return air ducts in commercial buildings (shopping malls, hotels, office buildings), hospitals, schools, factories, and other central air conditioning systems.