In various industries, tanks and containers play a crucial role in storing a wide range of substances. However, the accumulation of contaminants within these structures can lead to severe consequences, including product spoilage, health hazards, and regulatory non -compliance. Traditional manual cleaning methods are not only labor - intensive and time - consuming but also pose significant risks to workers.

The global industrial cleaning market, which includes tank and container cleaning services, was valued at approximately 45billion in 2023,with a compound annual growth rate(CAGR) of 5.28 - 10 billion annually. In the United States, the industrial cleaning services industry contributed over $5 billion to the GDP in 2022, according to IBIS World. These businesses play a vital role in ensuring the smooth operation of various industries by maintaining the hygiene and safety of storage vessels.

Many industries are subject to strict regulations regarding the cleanliness and safety of their storage vessels. For example, the Food and Drug Administration (FDA) in the United States has guidelines for the sanitation of food storage tanks, and the European Food Safety Authority (EFSA) has similar regulations in Europe. Clean tanks and containers ensure the smooth flow of materials, prevent blockages, and maintain the quality of the stored substances. This leads to increased productivity and reduced downtime. Regular cleaning can prevent costly repairs, product spoilage, and legal liabilities associated with contamination.

There are two common cleaning ways: manual cleaning and robotic cleaning.

In the early days, tank and container cleaning was primarily done manually. Workers used basic tools such as mops, buckets, and simple brushes. Later, fixed nozzles and low - pressure hoses were introduced, but these had limited cleaning effectiveness, especially in large and complex - shaped vessels.

Manual cleaning involves workers entering the tanks or containers and using tools such as brushes, scrapers, and high - pressure hoses to remove contaminants. This method is often used for small - sized or irregularly shaped vessels. However, it has several disadvantages. It is labor - intensive, time - consuming, and poses significant risks to workers, including exposure to hazardous chemicals, confined space hazards, and physical injuries.

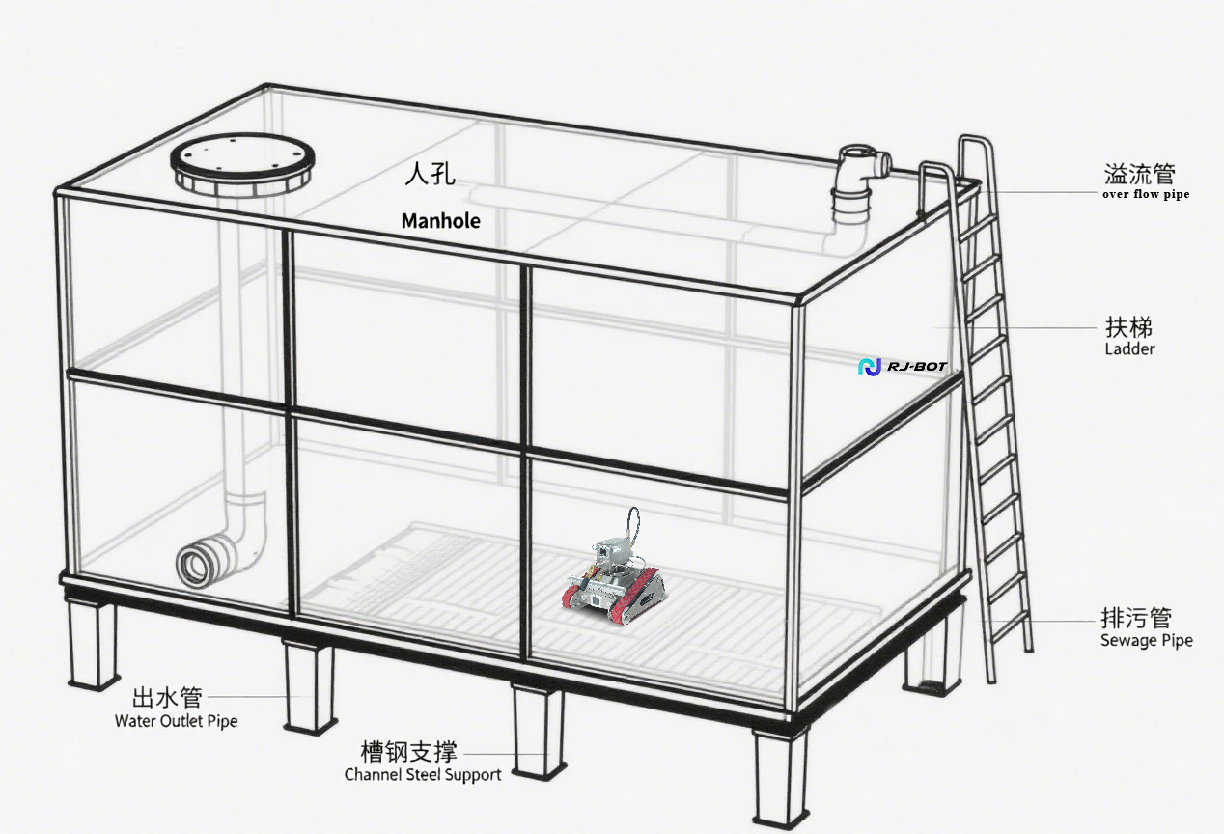

Robotic cleaning uses specialized robots, to clean tanks and containers. These robots are equipped with various cleaning mechanisms, such as high - pressure nozzles, brushes, and sensors. They can access hard - to - reach areas, provide consistent cleaning, and reduce the risk to human workers. Robotic cleaning is becoming increasingly popular in industries where safety, efficiency, and consistency are paramount.

Tank cleaning technology has evolved through three stages:

1980s–1990s, high-pressure water jetting (using powerful pumps to remove stubborn contaminants) improved efficiency;

2000s, automated systems with sensors and PLCs enabled precise, adaptive cleaning based on contamination types;

2010s–present, robotic cleaners with 360° nozzles, HD cameras, and remote control navigate complex tanks while providing real-time monitoring.

Studies have shown that robotic cleaning can reduce water consumption by up to 40% compared to manual methods. It can also achieve a 99% contaminant removal efficiency, compared to around 80 - 90% for manual cleaning. The cleaning time can be reduced by up to 60% in some cases.

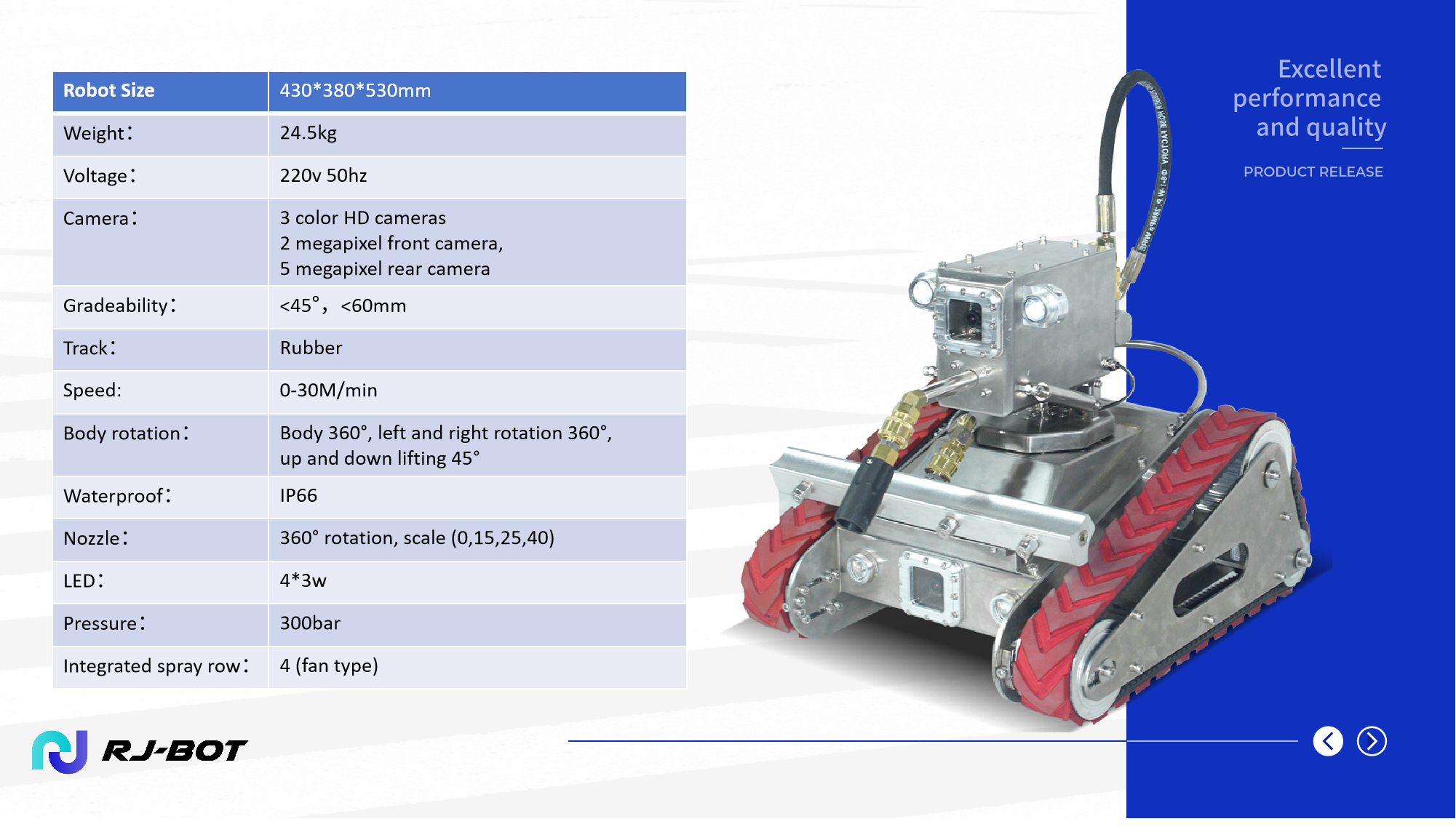

360° Nozzles

Rubber Tracks

Wide Spray Range

4300 psi / 300 bar Pressure Resistance

IP66 Waterproofing

Remote Control

Adjustable Camera

The RJ-BOT S6 robot redefines tank cleaning with its integrated advanced features for superior performance,safety,and efficiency. Its 360°rotating nozzles ensure complete coverage,reaching every corner and crevice,while the wide spray range covers large areas in fewer passes,slashing cleaning time.Capable of withstanding 4300psi / 300 kg pressure, it blasts away stubborn contaminants like oil,grease,and rust,leaving tanks hygienic. The rubber-track mobility grips slippery,uneven surfaces—slopes,rough floors—without tank damage,and IP66 waterproofing protects it in harsh,wet,or chemical-laden environments. Operators control the bot remotely from a safe distance,avoiding confined-space risks.An adjustable HD camera provides real-time visuals to monitor progress and fine-tune cleaning parameters(pressure,nozzle angle,duration).

This all-in-one solution cuts labor costs,eliminates the need for water removal or tank disassembly(reducing safety hazards),and meets the highest cleaning standards—potentially eradicating Sick Building Syndrome.A smarter,safer,and more efficient way to clean.

The accumulation of chemical residues in irregularly shaped tanks (e.g., non-uniform geometries with weld seams, dead zones, or complex internal structures) poses significant risks to indoor air quality (IAQ) when cleaning is irregular or ineffective. Studies confirm that stagnant

contaminants—such as volatile organic compounds (VOCs) from hydrocarbons, microbial metabolites, and corrosion byproducts—off-gas progressively into adjacent spaces, contributing to Sick Building Syndrome (SBS) symptoms including headaches, mucosal irritation, and cognitive dysfunction (WHO, 1983; Mendell et al., 2002).

Irregular tanks often contain "blind spots" (e.g., sharp corners, pipe connections) where conventional cleaning methods (manual brushing, standard nozzles) fail to remove 100% of residues (API RP 2028, 2013). Without 360° rotary nozzle coverage or robotic precision cleaning, these trapped pollutants foster biofilm formation (per CDC guidelines on microbial risks in industrial systems) and sustain chronic VOC emission. For example, a 2018 NIOSH investigation linked persistent SBS cases in chemical storage facilities to untreated tank vapors infiltrating HVAC systems (NIOSH Report No. 2018-0012).

Robotic systems with 360°nozzles achieve >95% contaminant removal efficiency in complex geometries, while IP66-rated waterproofing prevents cross-contamination from cleaning agents. Such methods align with OSHA’s General Duty Clause (§5(a)(1)) requiring employers to maintain hazard-free environments, directly reducing SBS precursors like airborne formaldehyde and benzene (EPA IAQ Standards, 2020).

Tanks and containers are essential components in many industries, but their proper cleaning and maintenance are often overlooked. Unclean tanks can lead to a wide range of problems, including health risks, product quality degradation, and equipment damage. Traditional manual cleaning methods are no longer sufficient to meet the demands of modern industries. Robotic cleaning solutions, such as the RJ - BOT, offer a safe, efficient, and cost - effective alternative. With its advanced features, including 360° nozzles, rubber tracks, high - pressure resistance, and remote control, the RJ - BOT is revolutionizing the way industries clean their tanks and containers. As the demand for higher hygiene standards and regulatory compliance continues to grow, the adoption of robotic cleaning technology is likely to increase, ensuring a safer and more sustainable future for various industries.

LEVIN, H. (2005). National Expenditures for IAQ Problem Prevention or Mitigation. Lawrence Berkeley National Lab (EPA).

MarketsandMarkets (2023). Industrial Cleaning Market by Type & Region – Global Forecast to 2030.

IBISWorld (2022). Industrial Cleaning Services in the US – Industry Report.

HSE (UK, 2021). Confined Spaces Regulations in Industrial Tanks.

WHO (2018). Guidelines for Safe Drinking Water in Industrial Tanks.

JettyRobot (2022). Case Studies on Automated Tank Cleaning.

CDC (2012). Investigation of the 2011 E. coli Outbreak in Europe.

WHO (2020). Foodborne Disease Outbreaks in Industrial Storage Systems.

Mendell, M.J.et al. (2002). "Indoor Airborne Chemicals and Symptoms". Environmental Health Perspectives, 110(Suppl 4), 647-653.

API RP 2028. (2013). Cleaning and Purging of Petroleum Storage Tanks. American Petroleum Institute.

NIOSH. (2018). Investigation Report: Chemical Storage Facility SBS Cases(Report No. 2018-0012).

EPA. (2020). Indoor Air Quality Guidelines for Volatile Organic Compounds. Washington, DC: US Environmental Protection Agency.