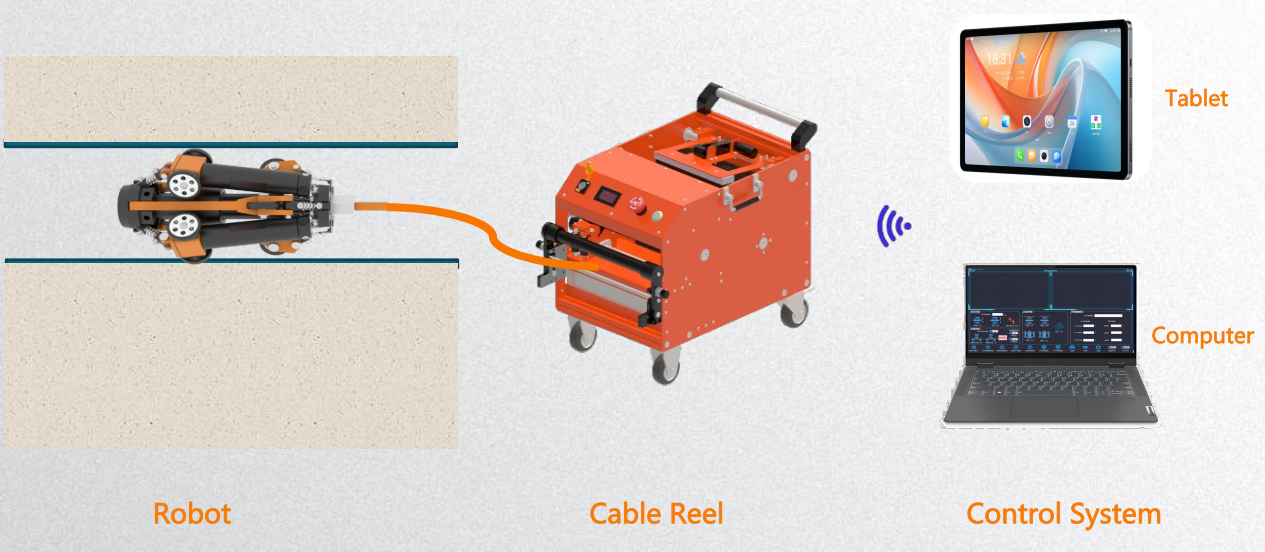

RJ-BOT F200 flexible vertical pipeline robot can be used for inspection and cleaning scenarios inside vertical pipelines; it achieves stable operation without falling through multi-technology synergy: by adjusting its linkage to change diameter, the drive wheels fully contact the inner wall of the vertical pipeline, generating gripping force via combined wheel-pipe friction and mechanical support; three 120°-evenly-distributed drive cabins paired with multiple power wheels enable all-wheel drive, providing continuous strong thrust for vertical climbing to counteract gravity; simultaneously, the robot automatically centers itself during vertical operation, maintaining attitude balance and uniform wheel-wall contact, with multiple technologies ensuring efficient task completion under vertical working conditions.

The inspection system is equipped with an 8 million pixels fixed-focus camera and a ring-shaped cold-light LED light source, capable of clearly capturing internal details of pipelines and accurately identifying defects such as cracks and corrosion in complex pipeline environments. The ring light provides uniform shadow-free illumination, ensuring no blind spots in dark areas, making it suitable for rapid inspection and hazard detection in municipal pipeline networks and industrial pipelines.

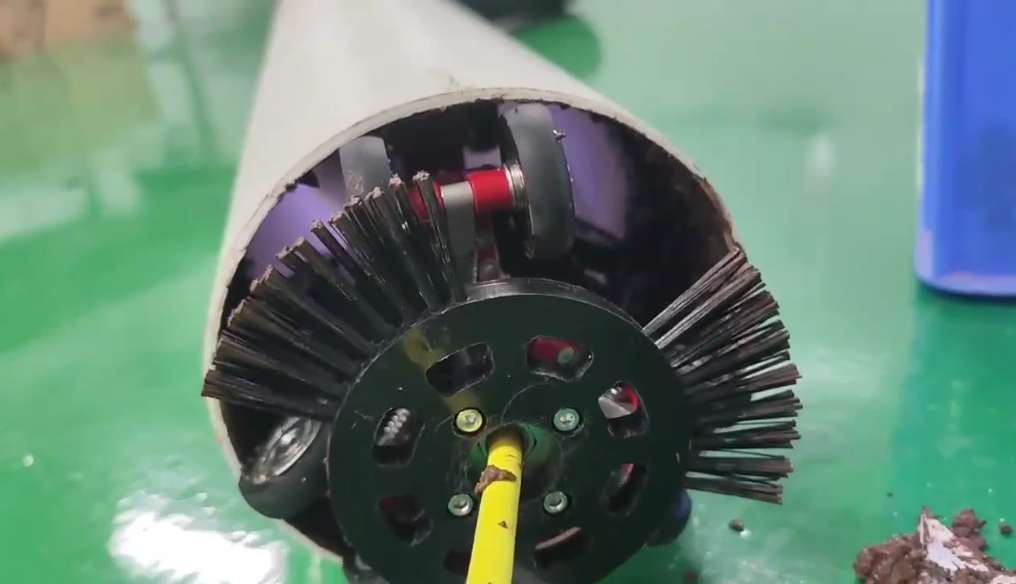

The robot is equipped with a 360-degree rotating brush cleaning mechanism that can comprehensively remove loose sediments and debris adhering to the inner walls of pipelines. The rotating brushes effectively sweep away dust, sand, and other loose materials from the pipeline surfaces, preparing a clean environment for subsequent inspection or maintenance tasks. The cleaning mechanism operates in coordination with the robot's movement, ensuring continuous brushing of the pipeline interior during forward motion.

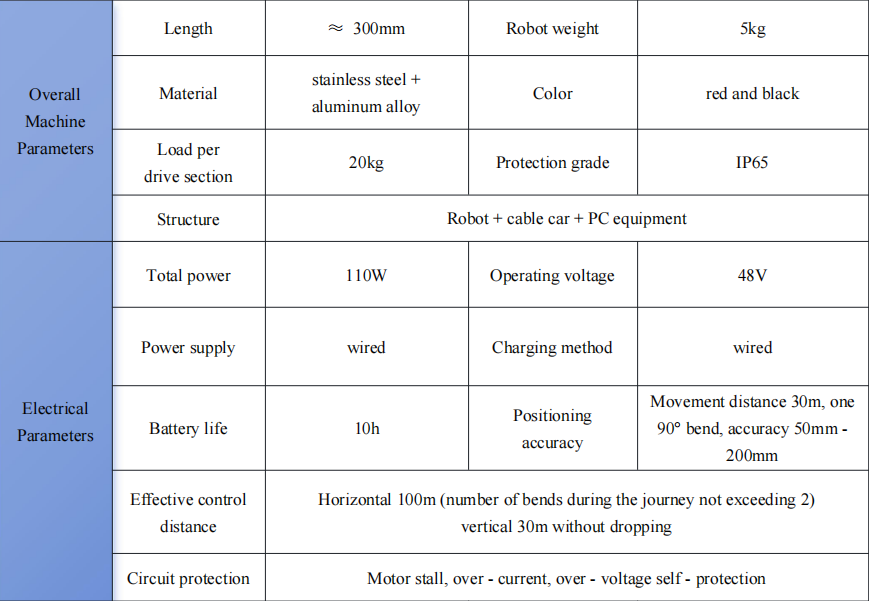

Overall Machine Parameters | Length | ≈ 300mm | Robot weight | 5kg |

Material | stainless steel + aluminum alloy | Color | red and black | |

Load per drive section | 20kg | Protection grade | IP65 | |

Structure | Robot + cable car + PC equipment | |||

Electrical Parameters | Total power | 110W | Operating voltage | 48V |

Power supply | wired | Charging method | wired | |

Battery life | 10h | Positioning accuracy | Movement distance 30m, one 90° bend, accuracy 50mm - 200mm | |

Effective control distance | Horizontal 100m (number of bends during the journey not exceeding 2) vertical 30m without dropping | |||

Circuit protection | Motor stall, over - current, over - voltage self - protection | |||

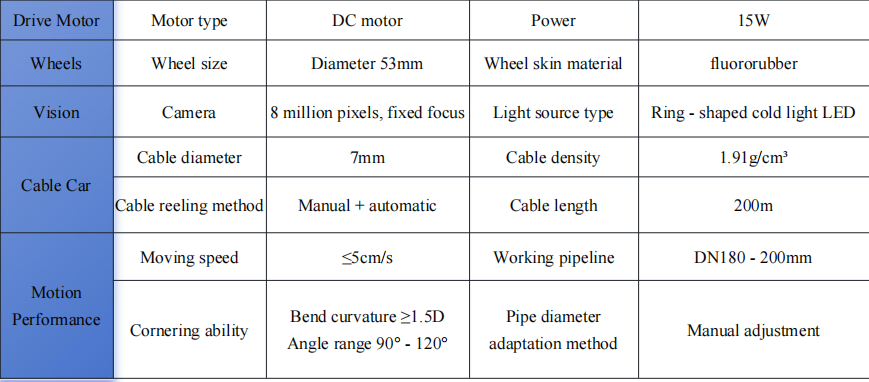

Drive Motor | Motor type | DC motor | Power | 15W |

Wheels | Wheel size | Diameter 53mm | Wheel skin material | fluororubber |

Vision | Camera | 8 million pixels, fixed focus | Light source type | Ring - shaped cold light LED |

Cable Car | Cable diameter | 7mm | Cable density | 1.91g/cm³ |

Cable reeling method | Manual + automatic | Cable length | 200m | |

Motion Performance | Moving speed | ≤5cm/s | Working pipeline | DN180 - 200mm |

Cornering ability | Bend curvature ≥1.5D | Pipe diameter adaptation method | Manual adjustment | |