Manual cleaning attempts to solve a systemic problem with surface-level effort. The RJ-Bot HVAC Cleaning Solutions offer the ultimate fantasy for any facility manager: total, verifiable mastery over the air quality and efficiency of your entire infrastructure.

Before we detail the tools that make it happen, here are the three promises you are buying:

Eliminate the root causes of "Sick Building Syndrome." Our system scrubs away the hidden dust, mold, and pathogens that live deep inside your ducts, restoring the air your occupants breathe to hospital-grade quality. The result is peace of mind and zero tenant complaints.

Dirty ducts choke airflow, forcing your HVAC systems to overwork and driving up energy costs. By restoring your ducts to their original, engineered efficiency, our cleaning solutions deliver a massive return on investment through significantly lower energy bills and an extended lifespan for your costly HVAC equipment.

Stop guessing. Every one of our solutions incorporates advanced camera and reporting technology, giving you irrefutable, timestamped video proof of the clean. You buy certainty, predictability, and a guarantee that your facility will pass any air quality inspection.

Solution 1 is designed for HVAC duct maintenance in commercial buildings, industrial facilities, and public infrastructure. Equipped with adaptive brush heads (nylon/carbon fiber dual modes), 1080P real-time imaging, and a high-performance vacuum module (2000Pa suction), the system handles duct diameters from 28-75mm, effectively removing dust, grease, and microbial contaminants while minimizing secondary dust dispersion. Its four-wheel-drive chassis and anti-slip tracks enable 30° slope navigation and complex pipeline layouts, with modular filter systems and a user-friendly interface significantly improving cleaning efficiency (3x faster than manual methods) and reducing operational costs.

Designed to adapt to different duct sizes, this system covers residential HVAC ducts (28-50mm) to industrial exhaust pipes (50-75mm). It ensures effective cleaning across various diameters using adjustable brush heads and flexible seals, making it particularly suitable for hotel ventilation systems and small factory duct maintenance.

Constructed with high-strength steel plate to enhance impact resistance, the body features a galvanized coating to prevent rust. This design ensures durability in humid basements or food factory environments, with an expected service life of over 5 years.

Equipped with a HD and wide-angle camera, it provides real-time visualization of duct interiors. Operators can view blind spots via a tablet, and videos are automatically saved as cleaning records for subsequent quality checks.

Featuring powerful vacuum suction, this port quickly collects dust from ducts, reducing secondary dust dispersion. It is especially suitable for environments prone to suspended particles, such as welding workshops or flour mills.

The single brush mode (nylon bristles) is used for precision ducts (e.g., in pharmaceutical factories), while the dual brush mode (carbon fiber bristles) tackles stubborn dirt (e.g., rust in chemical plants). Users can flexibly choose modes based on duct material.

The rubber tracks have surface protrusions to increase traction, preventing the device from sliding on oily or wet floors. This ensures stable contact between the cleaning head and duct walls, reducing operational risks.

Videos are wirelessly transmitted to the operator’s device, allowing immediate adjustments to brush pressure or cleaning modes if blockages occur. This prevents blind operation that could damage the ducts.

A four-wheel steering system paired with an adjustable brush head enables the device to bypass internal brackets or bends in ducts. It is well-suited for complexly laid central air conditioning ducts.

Solution 2 is suitable for cleaning air ducts in large factories, large supermarkets, schools/hospitals, subways/airports (applicable duct size: 400mm - 1200mm). It supports tablet operation, and is equipped with 3 HD cameras to record the cleaning process. It can realize 60m long - distance cleaning and free up - down movement, and is equipped with a high - power fan for dust blowing. The body is made of 304 stainless steel, supporting a maximum extension of 400mm and a maximum cleaning height of 1200mm.

Tablet control:

Designed to enable remote operation, allowing users to adjust working parameters and monitor the device status conveniently from a distance, so as to improve operational flexibility and safety.

Engineered to capture comprehensive visuals of the cleaning process from multiple angles, which helps in documenting work details, facilitating post - operation analysis, and providing evidence for quality inspection.

Created to meet the demand of cleaning long - range ducts in one go, reducing the need for repeated positioning of the device and enhancing work efficiency when dealing with large - scale duct cleaning tasks.

Devised to generate strong airflow, which can effectively blow away dust, debris and other contaminants in ducts, ensuring thorough cleaning and improving the air quality of the duct system.

Intended to allow the device to reach different vertical positions freely, adapting to ducts with different heights and complex installation environments, so as to expand the applicable range of cleaning.

Made of 304 stainless steel to ensure the device has good durability, corrosion resistance and wear resistance, enabling it to work stably in harsh industrial environments such as oil - containing and humid places.

Designed to enable the device to adapt to ducts of different widths by extending, so that it can maintain a good working state and sealing effect when dealing with ducts with varying specifications.

Set to meet the cleaning needs of tall ducts in some large - scale industrial or commercial buildings, ensuring that the device can reach the upper - level ducts for effective cleaning.

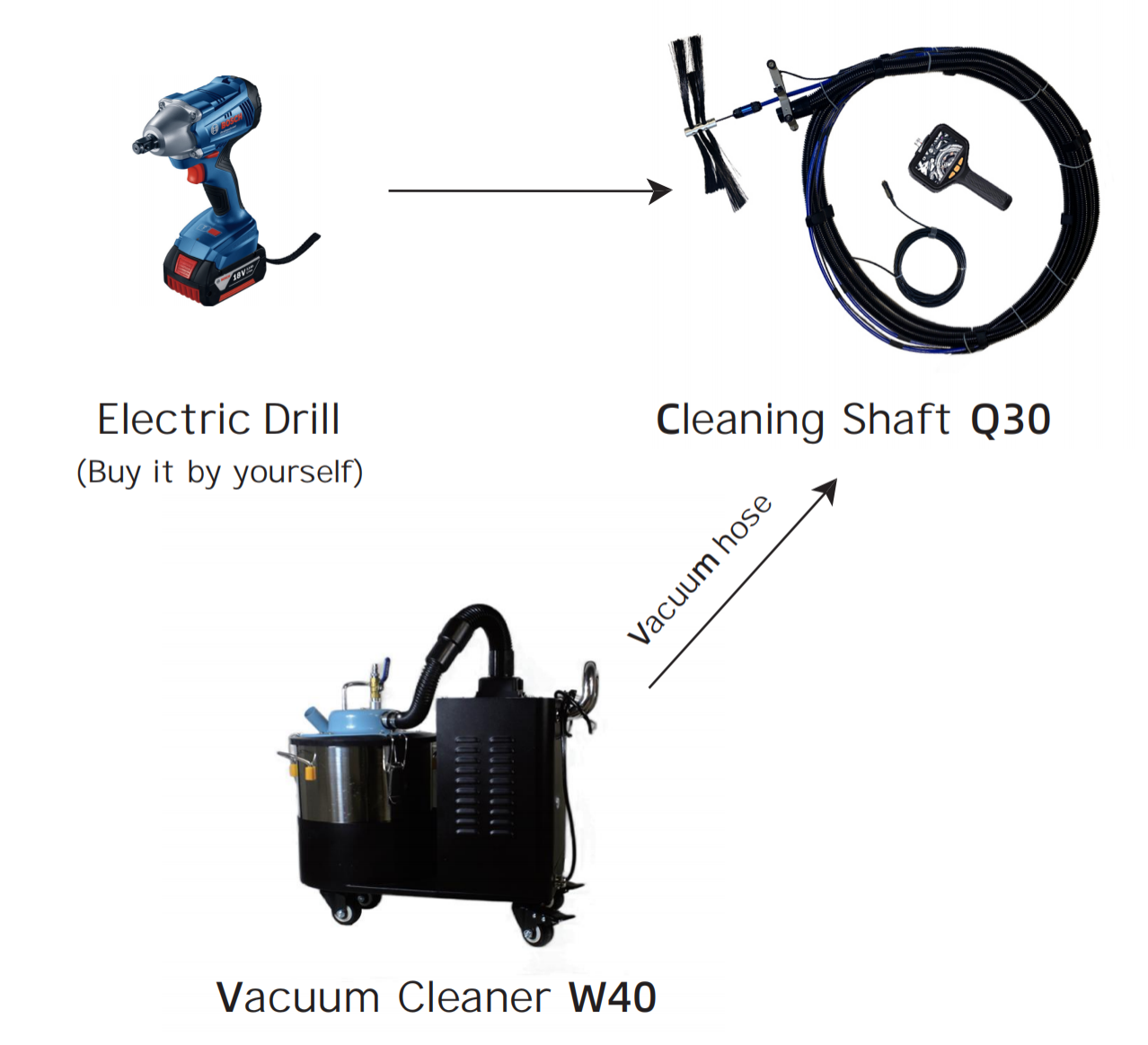

Solution 3: Professional Air Duct Cleaning Equipment for 75mm+ HVAC Systems.

Engineered for commercial ventilation ducts, the Q30 combines brush rotary cleaning, real-time HD monitoring, and integrated vacuum suction to eliminate contaminants.

Solution 4: All-in-One HVAC Duct Sanitization: Spin, Suction, Inspect.

Engineered for commercial 25-32cm ducts, R31 integrates 360° spherical brushing, built-invacuum, and 9" HD real-time monitoring to remove contaminants in one pass.

Designed to enable smooth movement across work areas and provide reliable braking when stopping. This facilitates easy repositioning of the device during oil suction tasks while ensuring it stays stable when not in motion.

Engineered to allow the suction hose or related components to rotate freely in all directions. It adapts to oil sources at various angles and positions, enabling more flexible operation during oil suction.

Created to prevent the device from slipping on oily or slippery surfaces (like factory floors). This ensures safe movement and stable operation even in environments where slippage is likely.

Intended to enclose the oil suction area, preventing oil splashing and diffusion. It also guides oil flow towards the suction inlet, improving suction efficiency and making oil collection easier.

Devised to maintain the device’s balance during movement, oil suction, and other operations. This reduces the risk of tipping over and guarantees safe and continuous work.