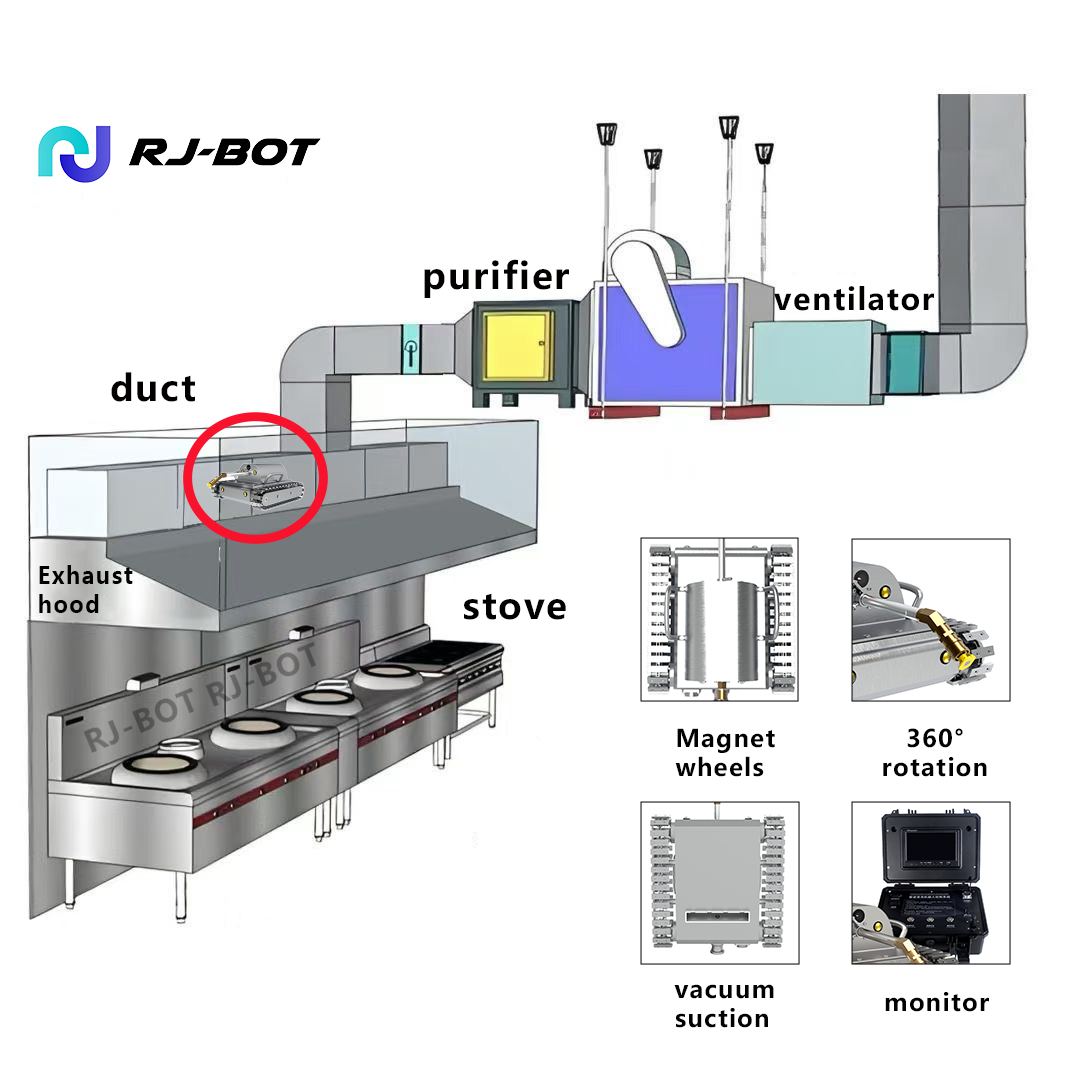

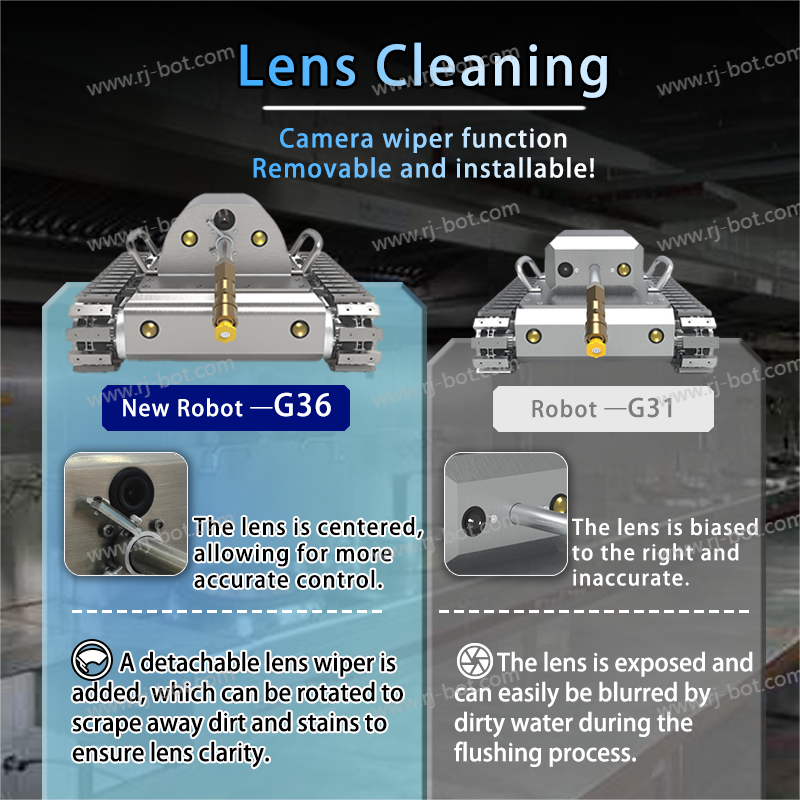

The G36 Commercial Kitchen Grease Duct Cleaning Robot is a state-of-the-art tool designed to tackle stubborn grease buildup in commercial kitchen exhaust systems, ensuring compliance with fire safety regulations. Engineered for ducts with diameters ≥280 mm (11 inches), this kitchen grease duct cleaning machine combines advanced technology and user-friendly operation to streamline grease duct maintenance in environments like school cafeterias, hotel kitchens, factory canteens, and government facilities. Compared with other robot, it upgraded water-proof function and camera's location, improving record efficiency and delivering safer, faster, and more reliable duct maintenance.

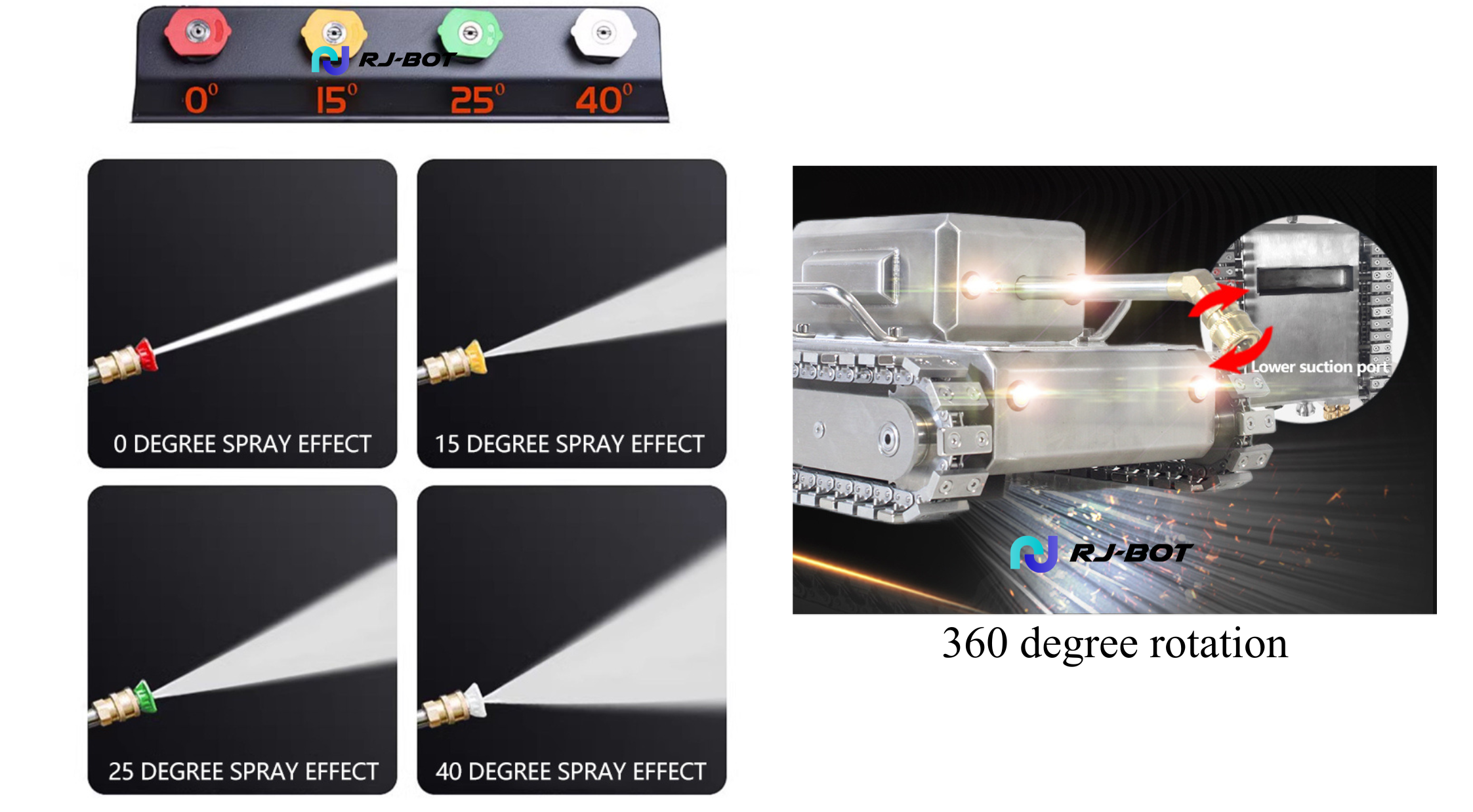

Equipped with a high-performance motor, this kitchen grease duct cleaning robot enables one-touch start for instant operation. The rotating nozzle dynamically adjusts angles (360° coverage) to scrub away hardened grease deposits, oil residues, and stuck debris—dramatically reducing manual scrubbing time and improving duct hygiene.

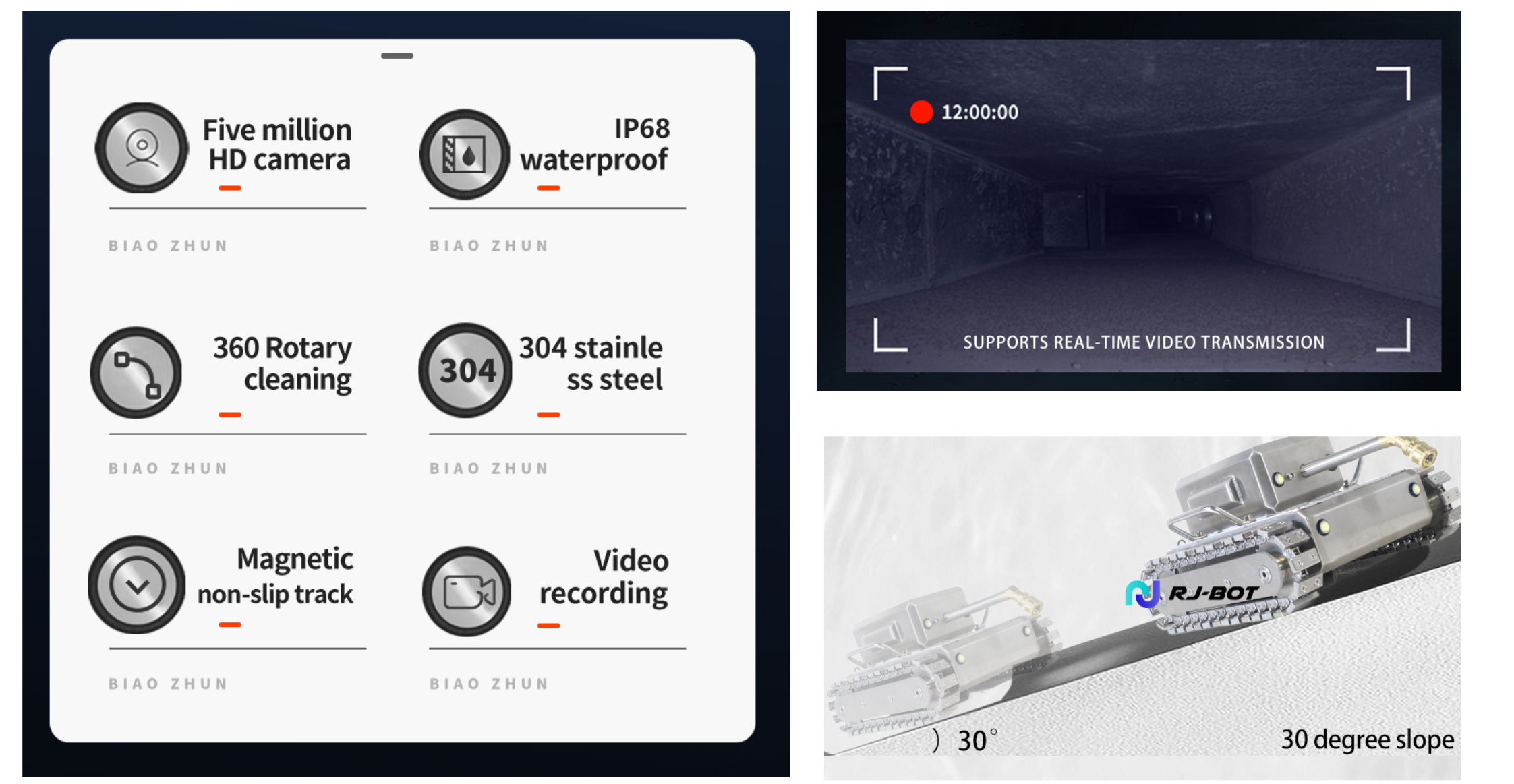

Our kitchen grease duct cleaning robot features dual front/rear HD cameras with built-in LED lighting, providing crystal-clear live video feedback to operators via a connected monitor. The operator can monitor duct interiors in real time, identify hidden fire hazards (e.g., accumulated lint, grease layers), and plan targeted cleaning, enhancing kitchen safety and compliance with fire codes.

The G36 kitchen grease duct cleaning robot is outfitted with a user-friendly dirty water suction port that detaches/reattaches in seconds for easy maintenance. Whether clearing light splashes or heavy sludge, the suction system adapts to your needs

Powered by an integrated 2,900 PSI water jet, this kitchen grease duct cleaning robot blasts through tough grease, food particles, and sludge. Paired with a built-in suction port, it simultaneously collects and recycles waste grease—preventing messy spills and ensuring eco-friendly disposal. Ideal for heavy-duty use in busy commercial kitchens.

Conquering the toughest duct layouts with magnetic wheels that grip vertical metal ducts securely (with a safety tether backup for added stability), this kitchen grease duct cleaning robot climbs slopes from 0° (flat) to 30° reaching previously hard-to-access areas like ceiling ducts or multi-level kitchen exhaust systems.

Reinforced waterproofing (IP65 rated) protects internal components from steam, water, and grease splashes. Corrosion-resistant stainless steel housing resists rust and wear, ensuring long-term reliability even in greasy, humid conditions.

Evaluation Dimension | Robot +High-Temp/High-Pressure + Suction + Chemicals | Steel Brush + Foam Machine Cleaning |

Cleaning Efficacy | ✔️Excellent | ⚪ Moderate |

Pipe Protection | ✔️ Zero Damage | ❌ High Risk of Damage |

Chemical Usage | ✔️ Precise & Controllable | ❌ High Pollution Risk |

Hygiene & Safety | ✔️ Fully Enclosed | ❌ Open-Environment Pollution |

Coverage | ✔️ No Dead Zones | ⚪ Human Limitations |

Efficiency | ✔️ High | ❌ Low |

Compliance & Environmental | ✔️ Excellent | ❌ Poor |

Long-Term Cost | ✔️ Low | ❌ Hidden High Costs |

![]()

Manual scrubbing struggles to dislodge hardened grease, calcified deposits often only skim surfaces, leaving behind persistent buildup that re-clogs pipes quickly.

Human hands and basic tools can’t fully reach tight bends, pipe joints, or hard-to-access corners, leaving bacteria, mold, and foul odors lingering in hidden gaps, leading to recurring hygiene issues.

Manual cleaning requires direct contact with dirty water, sticky sludge, and harsh chemicals (e.g., bleach for disinfection), increasing exposure to skin irritation, infections, or accidental ingestion of harmful pathogens.

The slow, labor-intensive process demands hours of scrubbing (vs. minutes with machines), disrupting daily kitchen use. Frequent re-cleaning due to poor results also escalates costs for tools, detergents, or professional help.

G36 Parameter

Parameter | Value |

Weight | 14.8KG (Robot) + 7.45KG (Controller) |

Voltage | 220V/110V |

Material | 304 stainless steel |

Operating Height | 30cm or more |

Brand | RJ - BOT(G36) |

Purpose | Duct cleaning, Oil suction |

Cable length | 25m |

Speed | 6 - 7m/min |

Obstacles | 30° / 22mm |

Cleaning Method | Nozzle rotation cleaning |

Display | 1024 * 600 |

Recording | Video/photo |

Cameras | 2 pcs |

Lighting | 5 * 3W flash type LED light |

FAQ

A: G36 is the fourth-generation robot and an upgraded version of G31. G36 focuses on optimizing its body structure, enhancing water resistance, and extending the remote control distance to 25 meters. G31, as the third-generation model, has a control distance of 15 meters.

A: Both G36 and G31 are compatible with grease exhaust pipes (or kitchen ventilation ducts) with a diameter greater than 28 cm.

A: The robot’s 2900 psi high-pressure jet provides 360° rotation cleaning, ideal for curved pipes. Steel brushes only clean flat surfaces, leaving gaps and risking scratches on copper/aluminum pipes.

A: Customized products are available.

A: At least a high-pressure cleaning machine must be integrated, while high-temperature steam machines and degreaser sprayers can be selected based on requirements.