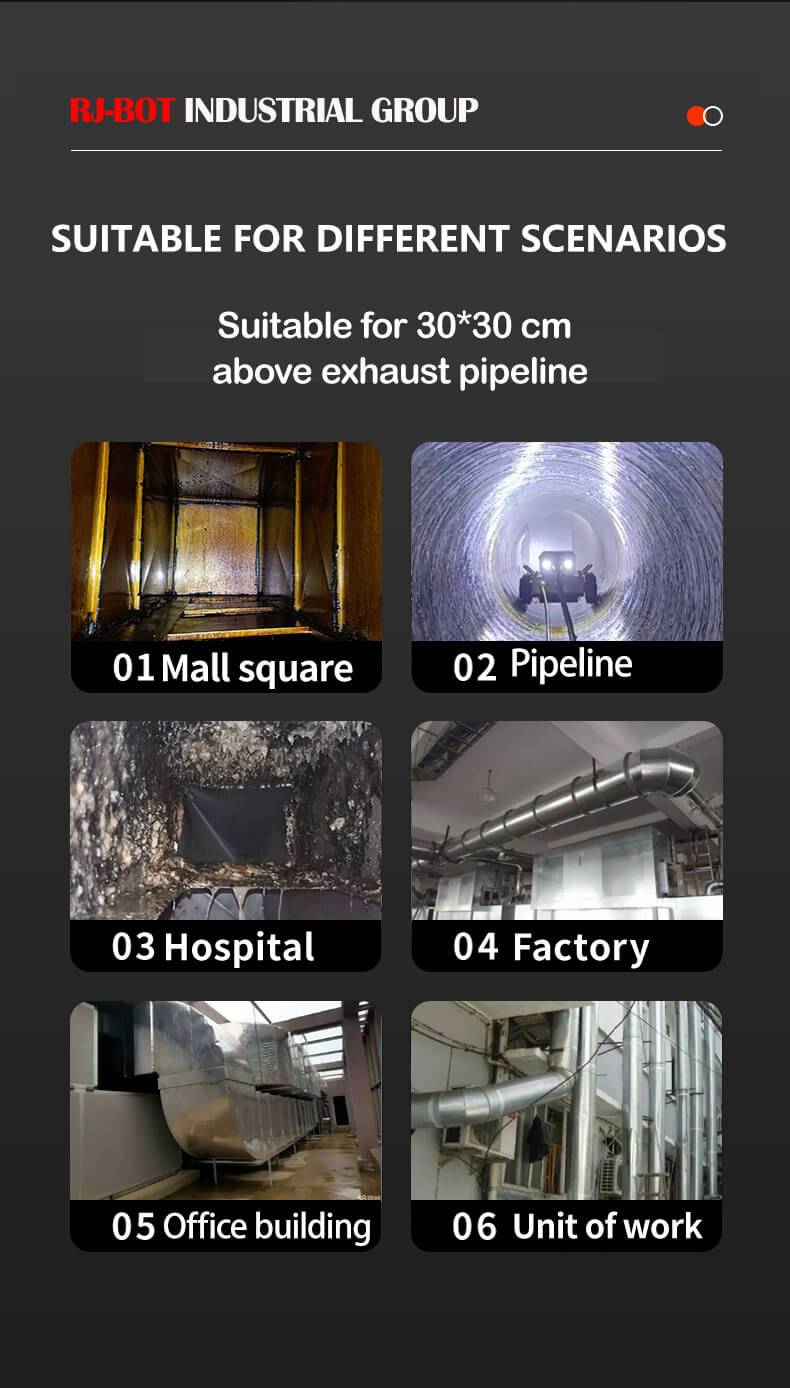

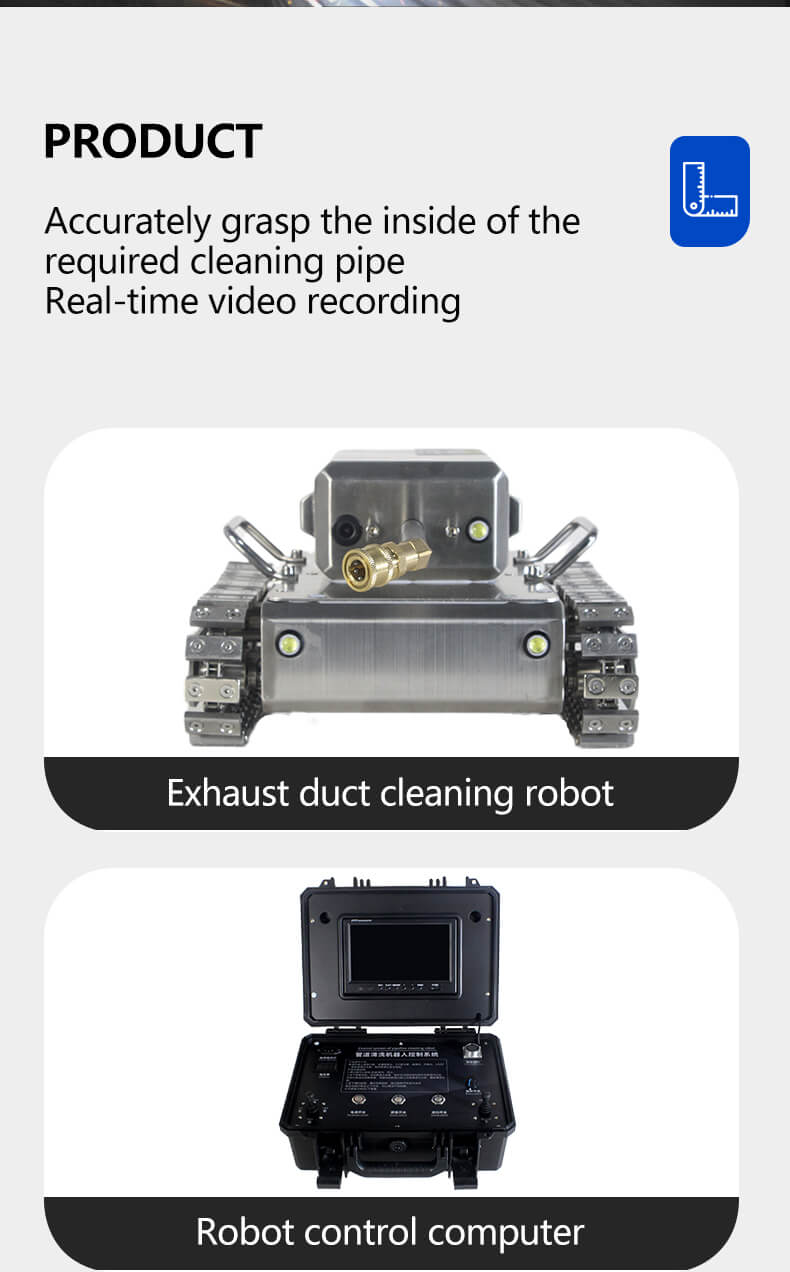

The G31 Grease Duct Cleaning Robot is a state-of-the-art tool designed to tackle stubborn grease buildup in commercial kitchen exhaust systems, ensuring compliance with fire safety regulations. Engineered for ducts with diameters ≥280 mm (11 inches), this robotic cleaner combines advanced technology and user-friendly operation to streamline grease duct maintenance in environments like school cafeterias, hotel kitchens, factory canteens, and government facilities.

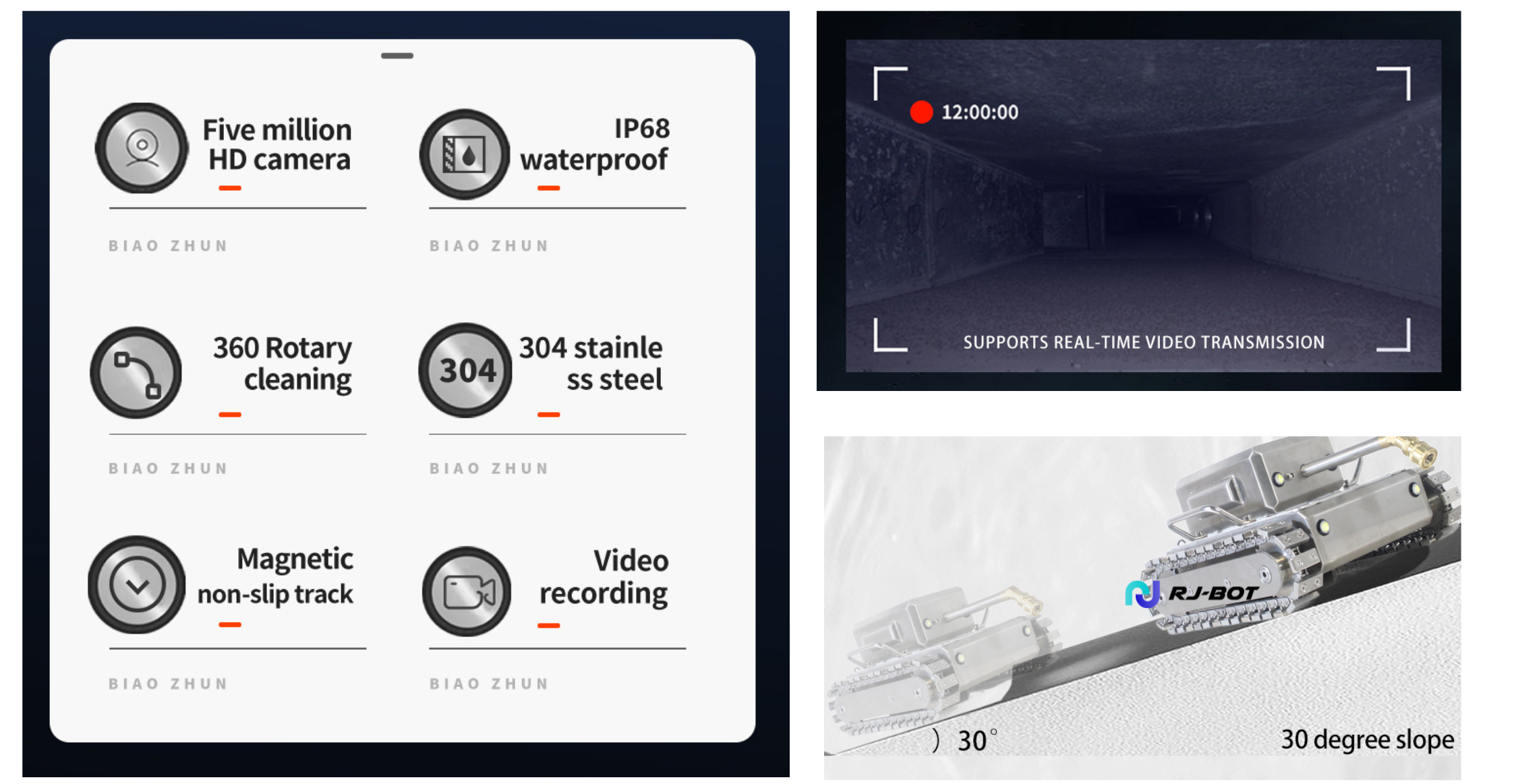

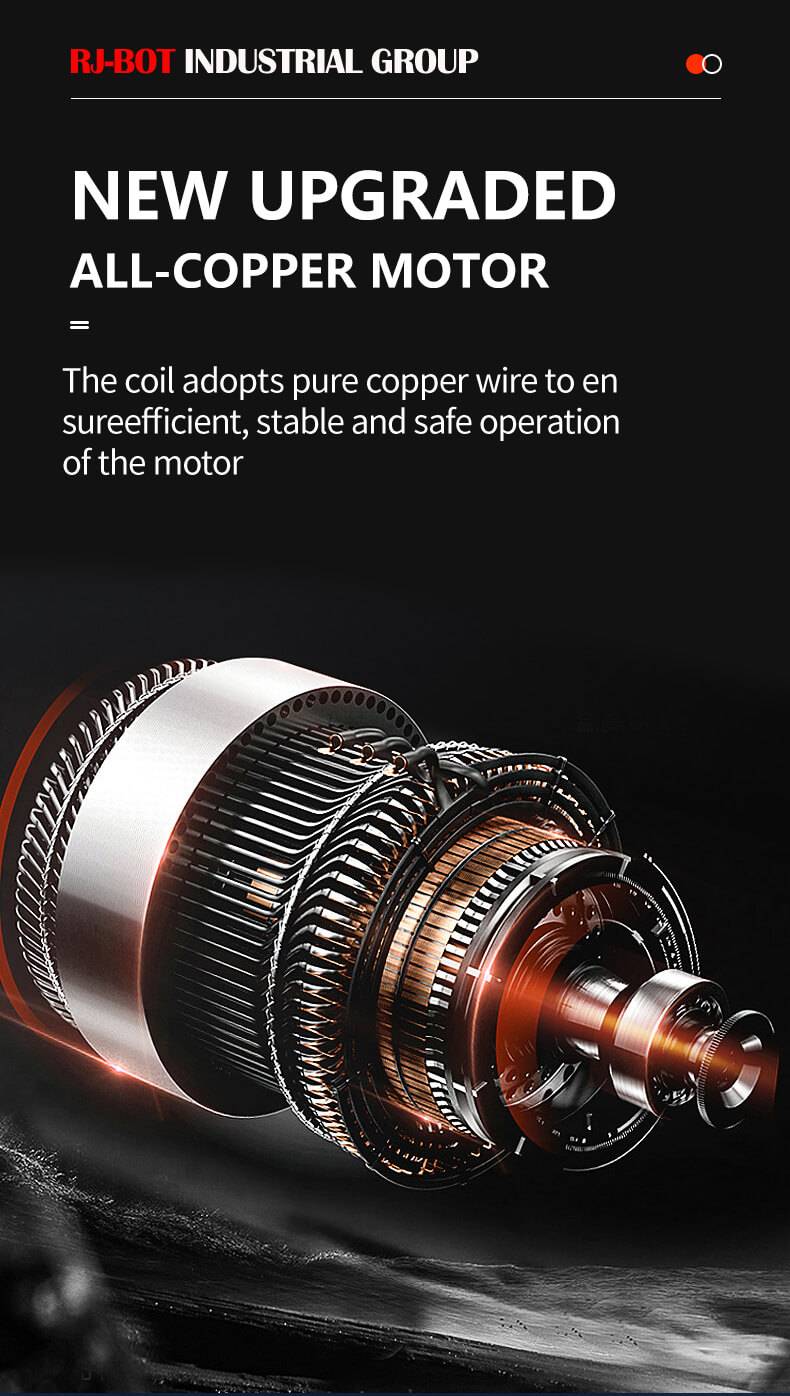

A high-performance motor enables one-button start operation, powering rotating nozzle to remove hardened grease deposits efficiently.

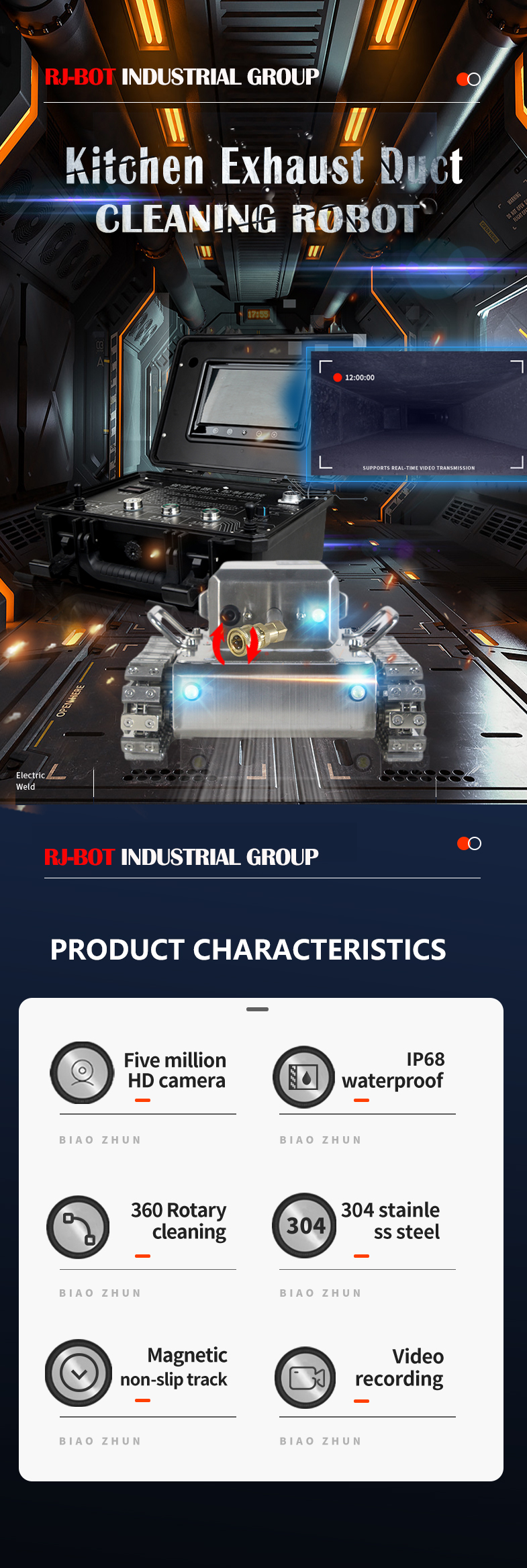

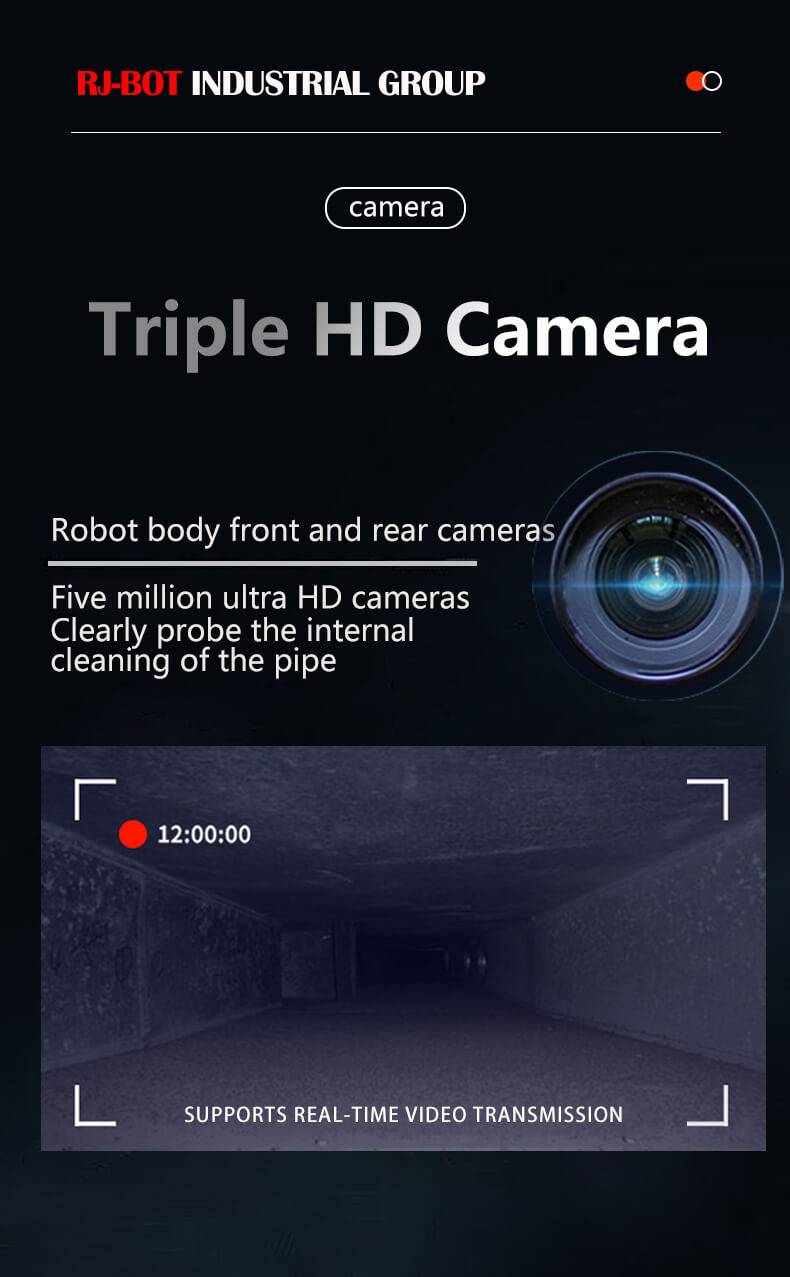

Dual front/rear HD cameras with LED lighting provide live video feedback, allowing operators to monitor duct interiors and identify hidden fire hazards.

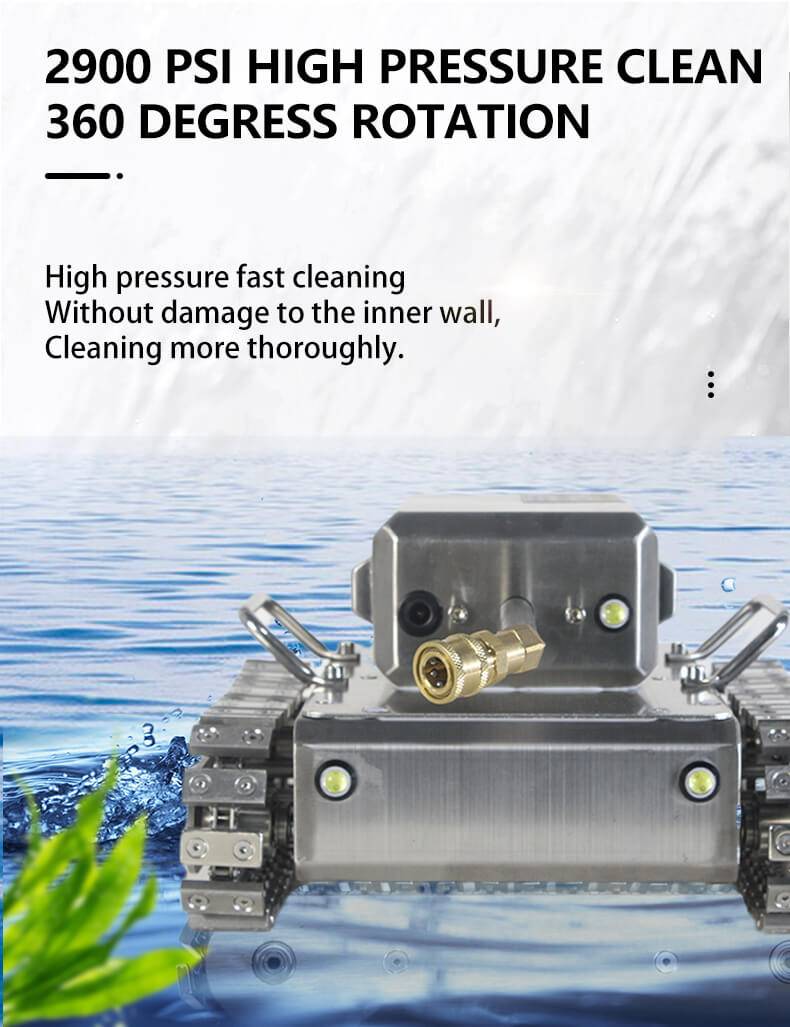

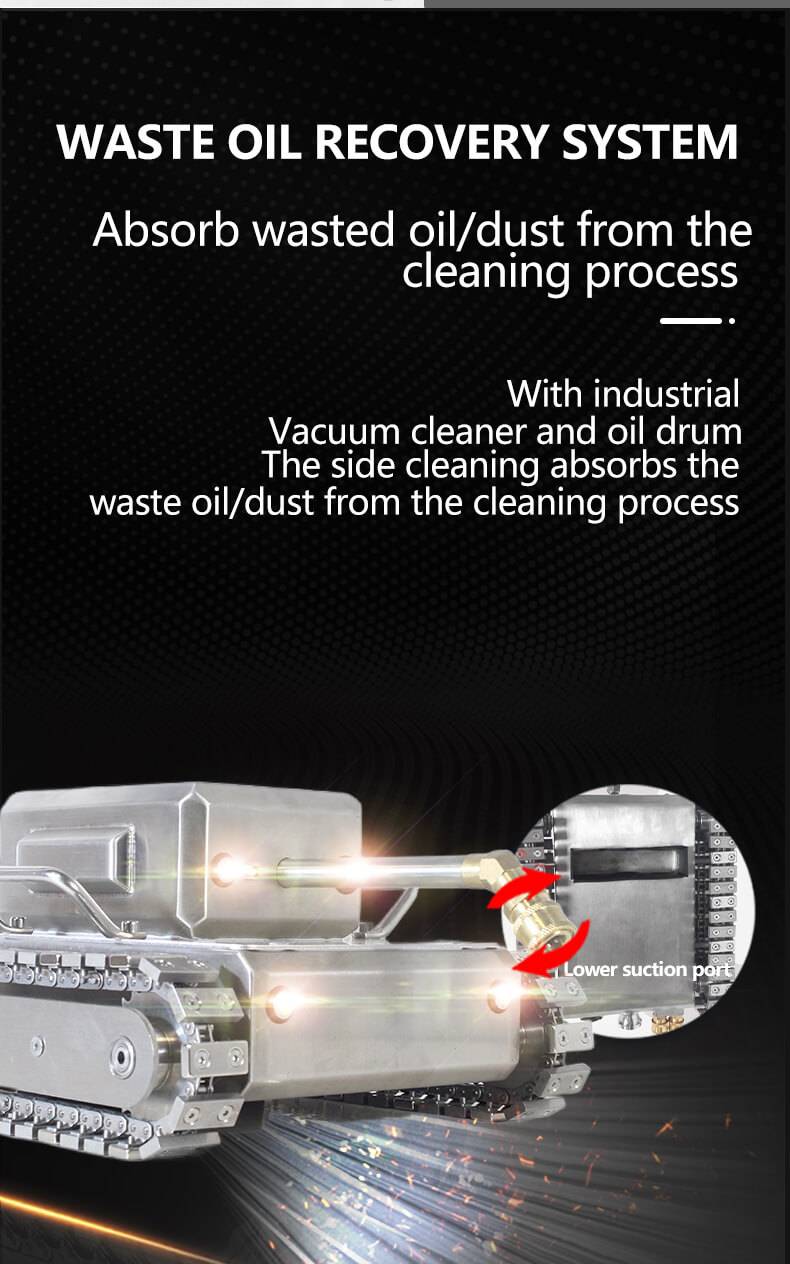

Integrated 2,900 PSI water jet breaks up debris, while the built-in suction port ensures waste grease is collected and recycled.

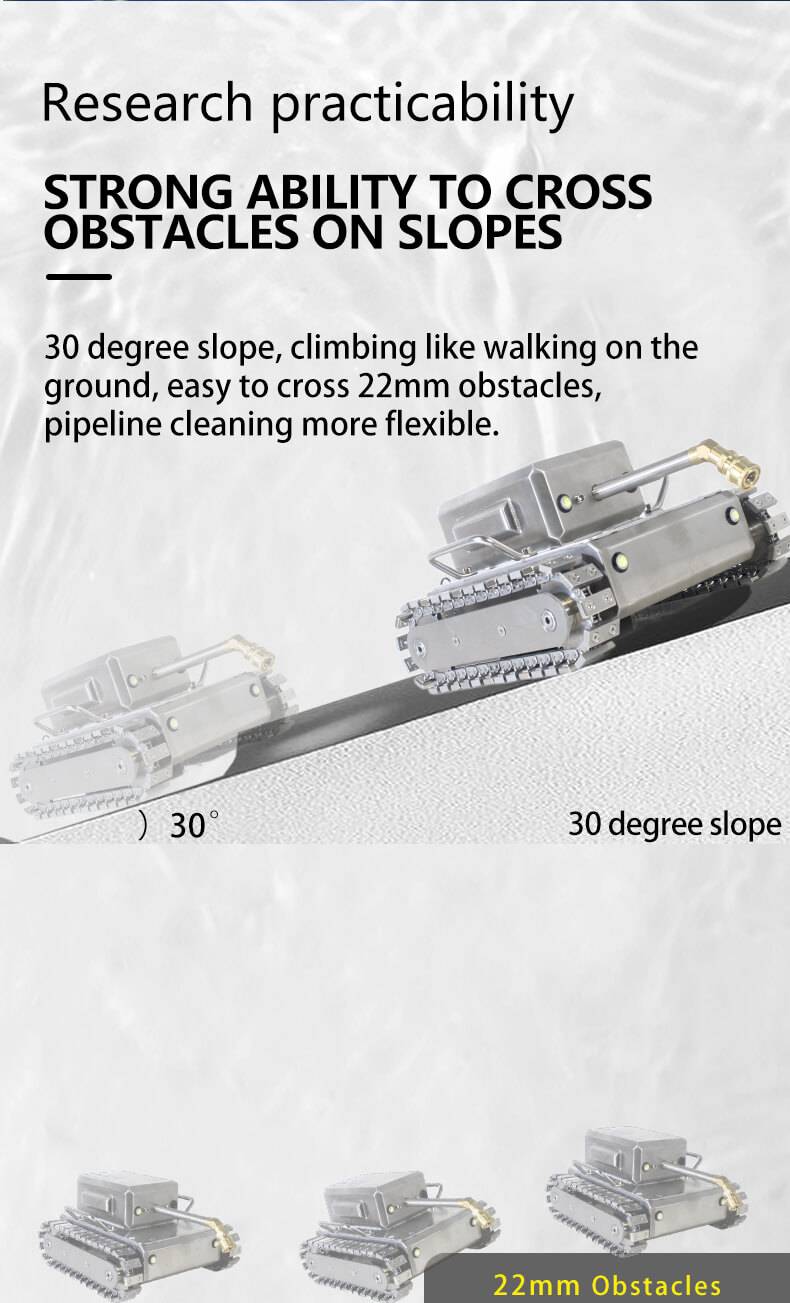

Magnetic wheels enable traversal of vertical metal ducts (with safety tether backup), ideal for complex commercial kitchen layouts.

IP65 waterproof rating ensures reliable performance in wet, greasy environments.

The dirty water suction port is attached, which can be disassembled and assembled freely as required.

Fire Risk Reduction: Eliminates flammable grease buildup, aligning with Regulatory Reform (Fire Safety) Order requirements.

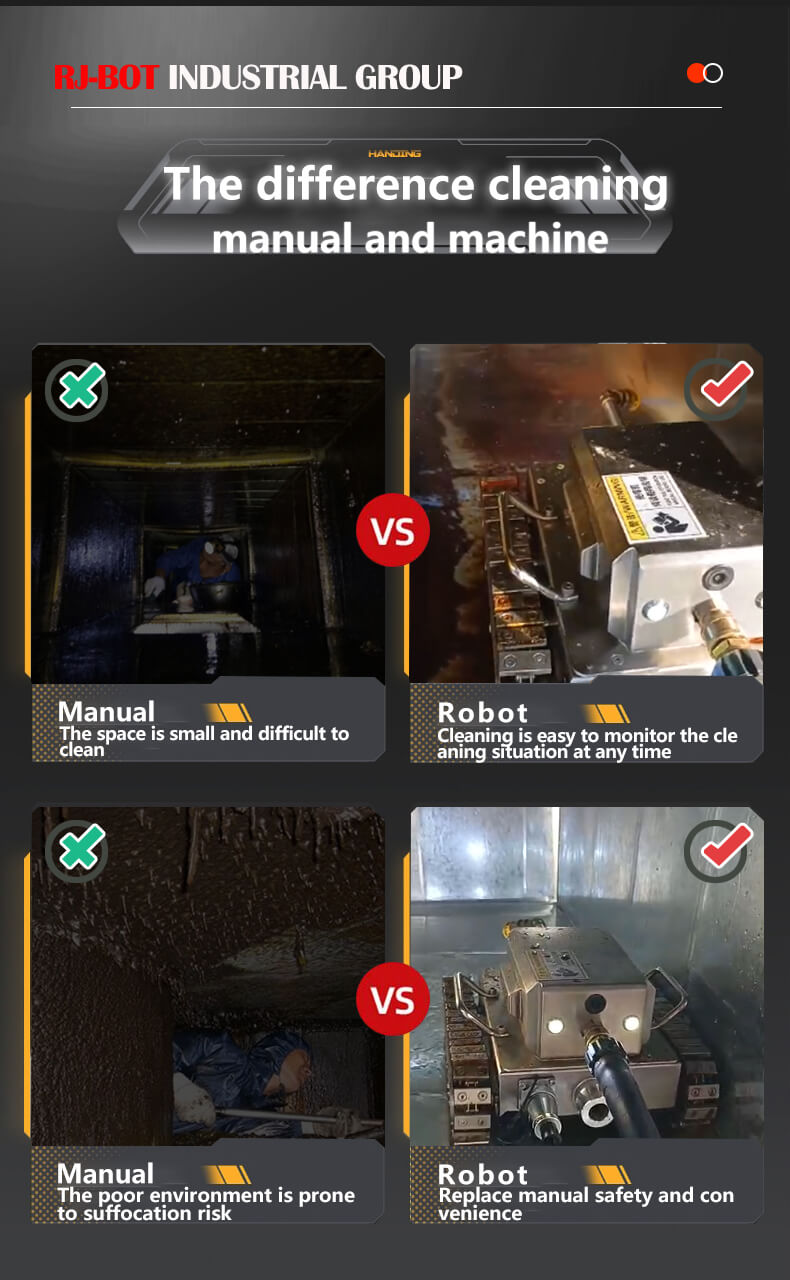

Time & Cost Savings: Cleans 15-meter ducts in a single pass, cutting labor costs by 40% compared to manual methods.

Eco-Friendly Operation: Waste oil recycling system minimizes environmental impact.

Restaurants needing compliant kitchen extract cleaning.

Facility managers prioritizing fire hazard prevention.

HVAC professionals seeking efficient grease duct maintenance tools.

| RJ-Bot | Others | |

| Robot | Support 360° no dead agle cleaning | left and right 120°, up and down 60° |

| No extra plastic tubes on the body. | The body has two plastic tubes, which will experience some wear and tear over time with prolonged use. | |

| Contral box | Simple and easy to operate, updated to the latest generation, keyless design. | Requires a key to start, an old version machine. |

High-pressure machine + heater + sprayer | We offer separate-function equipment: a high-temperature heater, a high-pressure machine, and a sprayer. Advantages: 1.Customizable Options: Customers can select the specific equipment they need, reducing costs. 2. Lower Maintenance Costs: If one function fails, only that unit requires repair, minimizing after-sales costs and failure rates. (An integrated high-temperature and high-pressure machine is also available for those who prefer an all-in-one solution.) Based on over ten years of sales experience, we have upgraded to the separate-function version for better flexibility and efficiency. | 1. High-Temperature, High-Pressure, and Sprayer – All-in-One Machine 2. Drawbacks of Multi-Function Integration: Combining multiple functions increases the likelihood of after-sales issues. If the sprayer is not thoroughly cleaned after use, it may cause damage to the machine, rendering both the high-pressure and heating functions inoperable. This significantly increases after-sales and repair costs. |

High-pressure machine | 200 Bar(Adjustable) pressure with suction function, two-level suction adjustment, quickly removes wastewater and waste oil. | 160 Bar pressure, no suction function. |

Oil recyle bucket | The separate oil recyle bucket makes it easier to pour out wastewater, allowing for faster disposal and saving time. | The oil suction barrel integrated with the vacuum cleaner requires disassembly and reassembly when the wastewater is full, slowing down operations and affecting work efficiency. The close proximity of wastewater and waste oil increases the risk of damaging the vacuum cleaner if mishandled. |

Chemical Sprayer | Equipped with dual pumps—if one pump fails, the backup pump can be used, ensuring uninterrupted workflow. | |

Heating machine | Diesel heater with fast heating speed, accelerating the cleaning process. | Eletric heating , slow heating speed |

Connection method of the entire set | The connection method of the entire product set has been upgraded to reduce after-sales issues. | Uses our traditional product connection method from several years ago. |

Industry share | In the commercial kitchen cleaning robot field, we have 12 years of experience and are a top player in the Chinese market. Our focus is exclusively on commercial kitchen cleaning robots and central air conditioning robots. | Other suppliers are not specialized in commercial cleaning equipment; their main expertise lies in selling tracked machine chassis and related products. |

FAQ

A: G36 is the fourth-generation robot and an upgraded version of G31. G36 focuses on optimizing its body structure, enhancing water resistance, and extending the remote control distance to 25 meters. G31, as the third-generation model, has a control distance of 15 meters.

A: Both G36 and G31 are compatible with grease exhaust pipes (or kitchen ventilation ducts) with a diameter greater than 28 cm.

A: The robot’s 2900 psi high-pressure jet provides 360° rotation cleaning, ideal for curved pipes. Steel brushes only clean flat surfaces, leaving gaps and risking scratches on copper/aluminum pipes.

A: Customized products are available.

A: At least a high-pressure cleaning machine must be integrated, while high-temperature steam machines and degreaser sprayers can be selected based on requirements.

Key Features of the RJ-BOT G31

High-Pressure Cleaning System

2,900 PSI Water Jet: Effortlessly dissolves stubborn grease and contaminants.

Dual Brushes with 360° Rotation: Scrubs duct walls thoroughly, leaving no residue.

Real-Time Inspection & Safety

Dual HD Cameras with LED Lights: Monitor duct interiors live to spot hidden fire hazards.

Magnetic Wheels: Safely traverse vertical metal ducts (with backup safety tether).

Efficiency Redefined

Clean 15 Meters/Hour: Perfect for busy kitchens needing fast, deep cleaning.

Waste Oil Recycling: Collects and recycles grease for eco-friendly disposal.

User-Friendly Design

One-Button Operation: Start cleaning in seconds—no technical expertise required.

Lightweight & Compact: Easy to transport, even in tight kitchen spaces.

The RJ-BOT G31 Grease Duct Cleaning Robot is engineered to tackle the toughest grease buildup in commercial kitchen exhaust systems, ensuring compliance with fire safety standards while saving time and labor costs. Designed for ducts ≥280 mm in diameter, this robotic cleaner is ideal for school cafeterias, hotel kitchens, factory canteens, and other high-traffic food service environments.

Fire Hazard Prevention: Eliminates flammable grease buildup, aligning with Regulatory Reform (Fire Safety) Order requirements.

Cost Savings: Reduces manual labor by 40% compared to traditional methods.

Compliance: Meets Grease standards for ventilation hygiene.

Durability: IPX4 waterproof rating ensures reliability in harsh, greasy environments.

Restaurants: Maintain compliance and avoid insurance penalties.

Hotel Kitchens: Ensure guest safety with spotless air quality.

Industrial Canteens: Streamline maintenance for large-scale facilities.