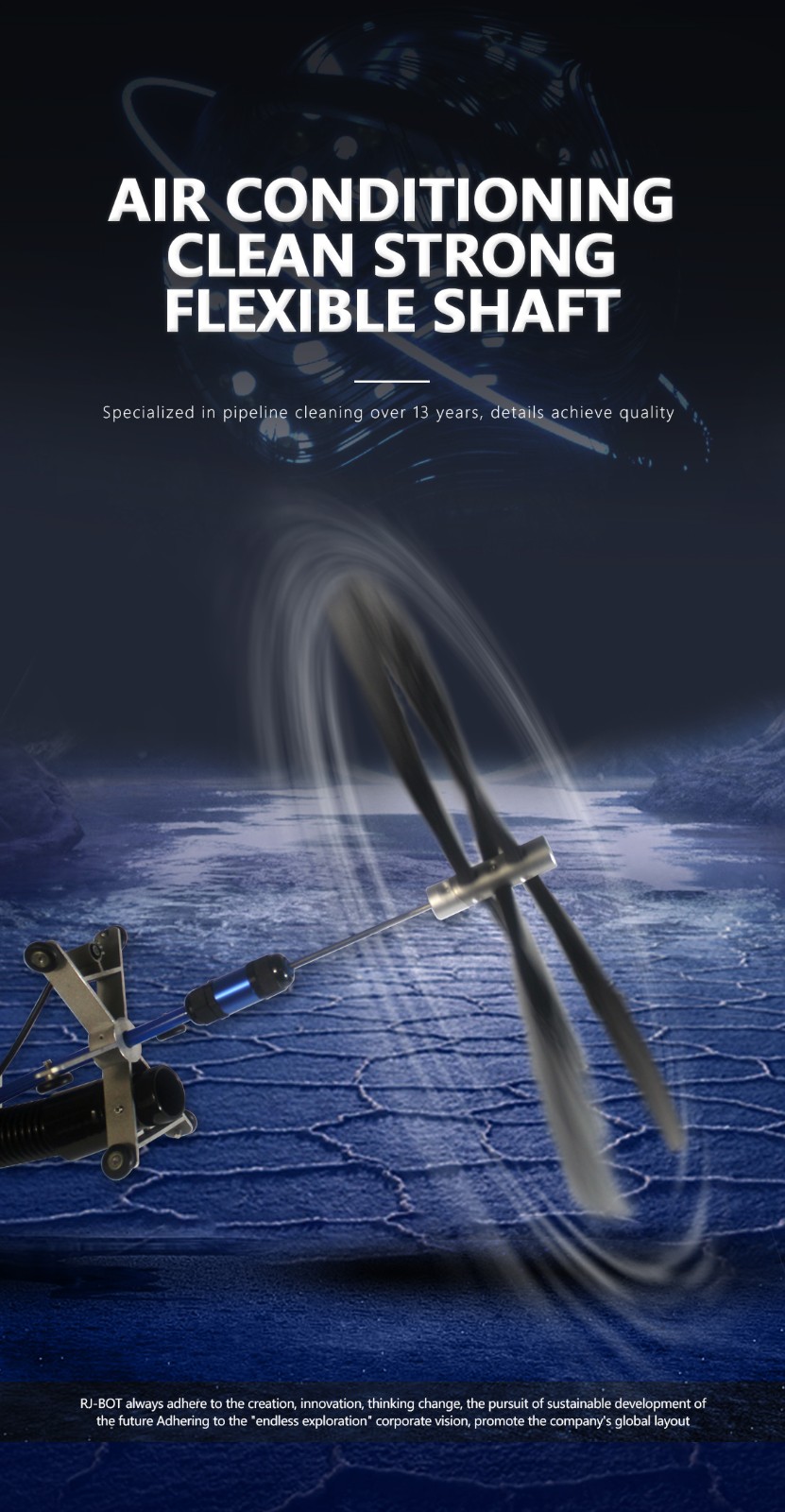

Professional Air Duct Cleaning Equipment for 75mm+ HVAC Systems

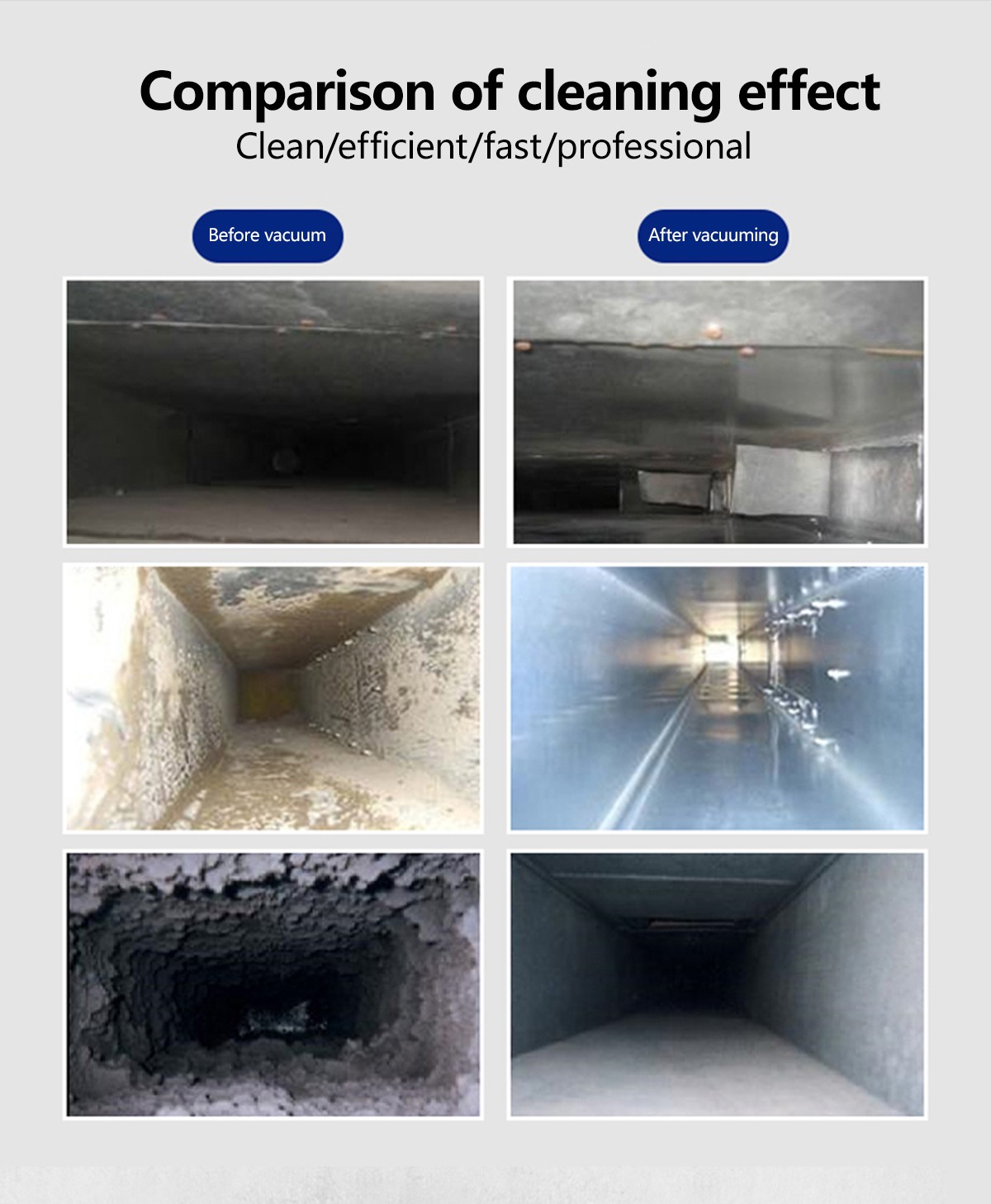

Engineered for commercial ventilation ducts, the Q30 combines brush rotary cleaning, real-time HD monitoring, and integrated vacuum suction to eliminate contaminants. Trusted by HVAC specialists in 37 countries for 12+ years.

Air Quality Collapse: Dust accumulation reduces airflow by 40%, circulating allergens in spaces

Pathogen Breeding Ground: Microbial growth in moist ducts increases respiratory disease risk by 300%

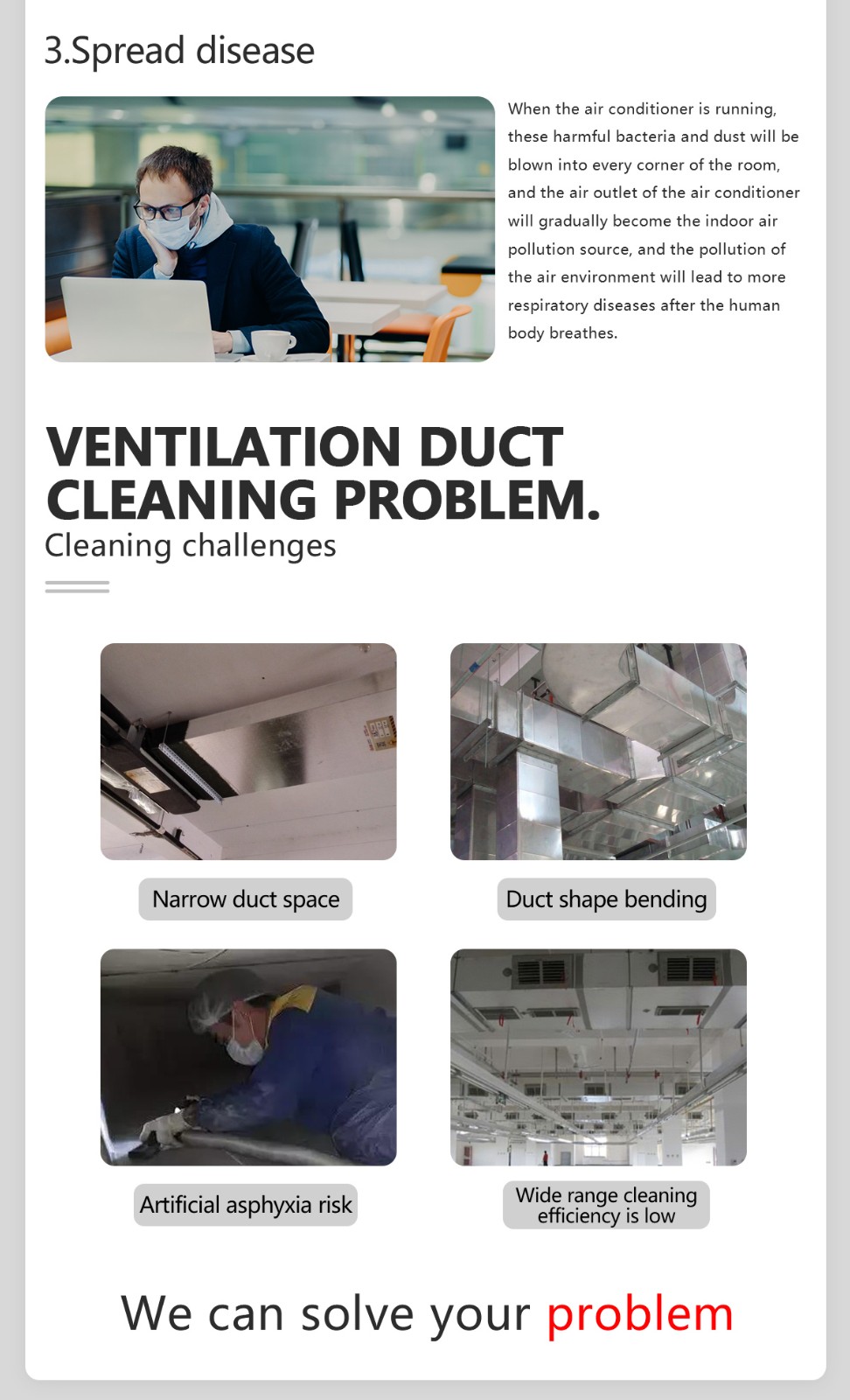

Fire Hazards: 22% of commercial fires originate from grease-clogged exhaust ducts

| Problem | Q30 Solution |

|---|---|

| Narrow/Bent Ducts | 8m Flexible Shaft navigates 45° bends |

| Manual Cleaning Risks | Remote Operation eliminates suffocation hazards |

| Low Efficiency | Brush Synced Rotation cleans 3x faster |

| Blind Spots | 360° Brush Coverage with no dead zones |

50NM torque pure copper motor shreds grease at 850 RPM - handles 200mm+ restaurant exhaust ducts.

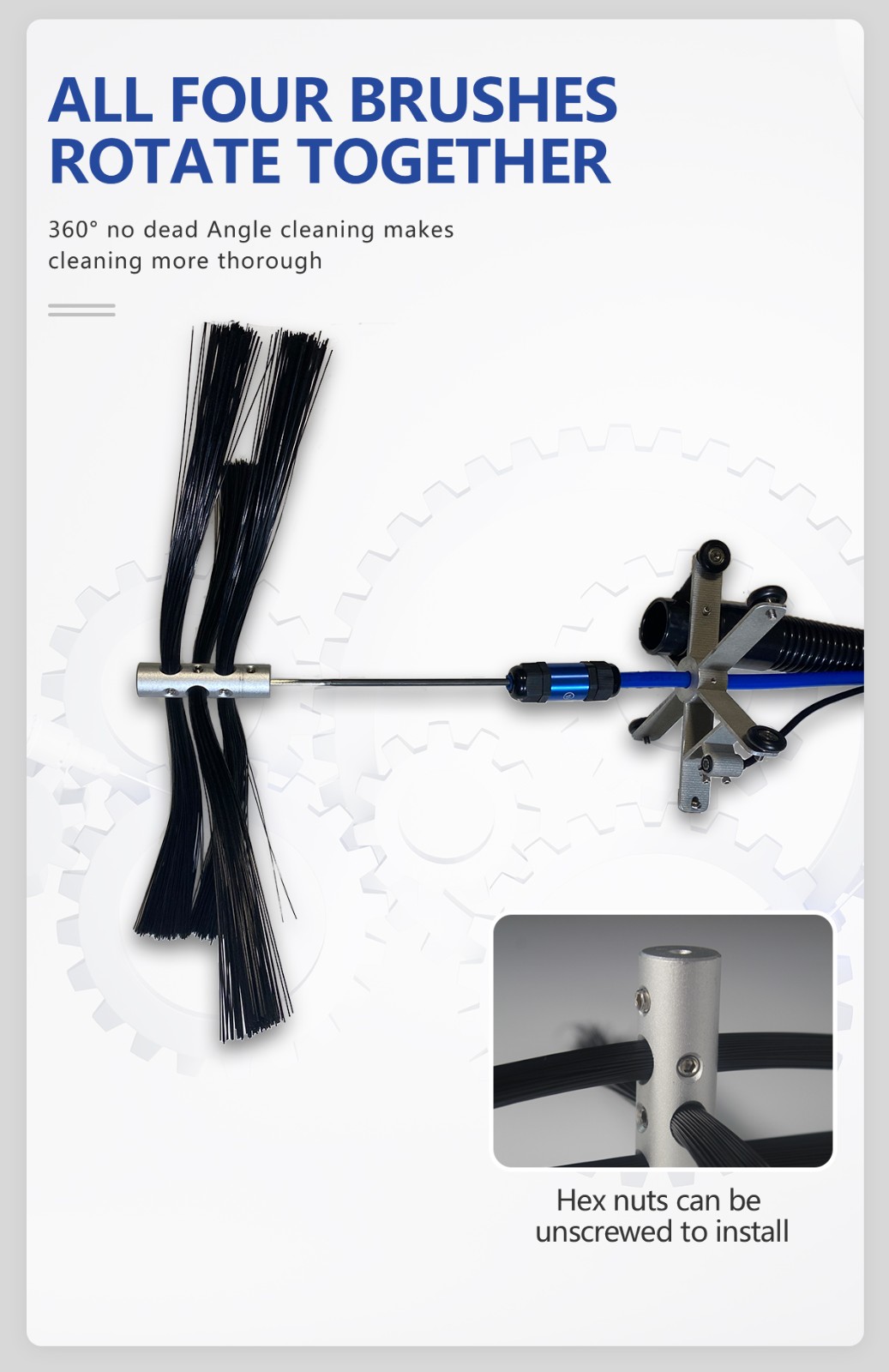

Four nylon brushes rotate synchronously to scrub every surface - 2x wall contact vs standard brushes.

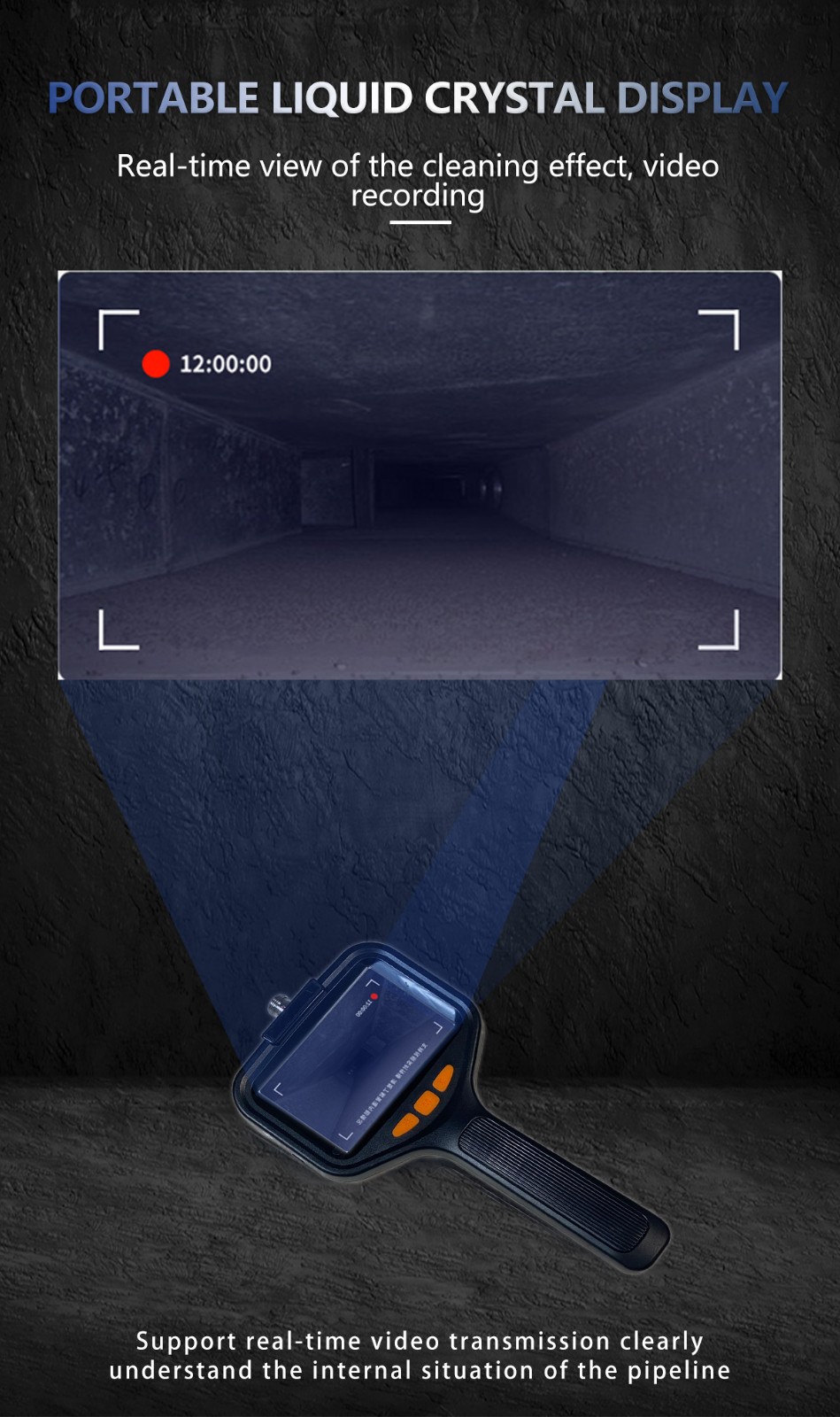

8" LCD display (1024×600) with LED lights reveals hidden buildup - record before/after proof videos.

Integrated vacuum hose (15m) with negative pressure captures debris during cleaning.

Extendable shafts (8m) & hoses (15m) adapt to complex duct networks in hospitals and factories.

Hex-nut brush mounting changes tools in 60 seconds - no specialized training needed.

PIPE RANGE Ø75-500mm

BRUSH SYSTEM 4x nylon rotary brushes

SHAFT MATERIAL High-elastic steel (45° bend radius)

DISPLAY 8" HD LCD (1024×600) with recording

VACUUM SUCTION Negative pressure via 15m hose

POWER SOURCE 50NM industrial electric drill

WEIGHT 5.4kg (handheld unit)

Hospital Isolation Wards: Sanitize infection-control ducts without disassembly

Factory Ventilation: Maintain 500mm metal ducts with corrosive dust

Historic Buildings: Navigate fragile 1920s tin ducts without damage

Insert flexible shaft into duct access point (75mm+).

» Activate brush system via drill trigger

» Monitor real-time progress on HD display

Save before/after footage for compliance reports.

A: Q30 uses flexible shaft cleaning and requires pairing with an external drill (as its power source)—a cordless drill is recommended to avoid breaking the flexible shaft from excessive power. By contrast, Q37 and Q40 are robotic cleaning models.

A: Both are electric flexible shaft cleaning devices. However, Q30 is equipped with a camera to visualize the pipe interior and a dust suction hose (compatible with vacuum cleaners). Q29 lacks these features, relying more on manual experience—which may result in certain blind spots in cleaning effectiveness.