The P24 Chemical Spray Machine is a professional device that efficiently softens stubborn stains (especially grease) by spraying chemical agents (e.g., specialized degreasers, softeners) . It targets stubborn grease problems that traditional physical cleaning methods (like rag wiping, dry sweeping) fail to resolve.

Note: This machine can be used with a cleaning robot to achieve optimal heavy grease cleaning results.

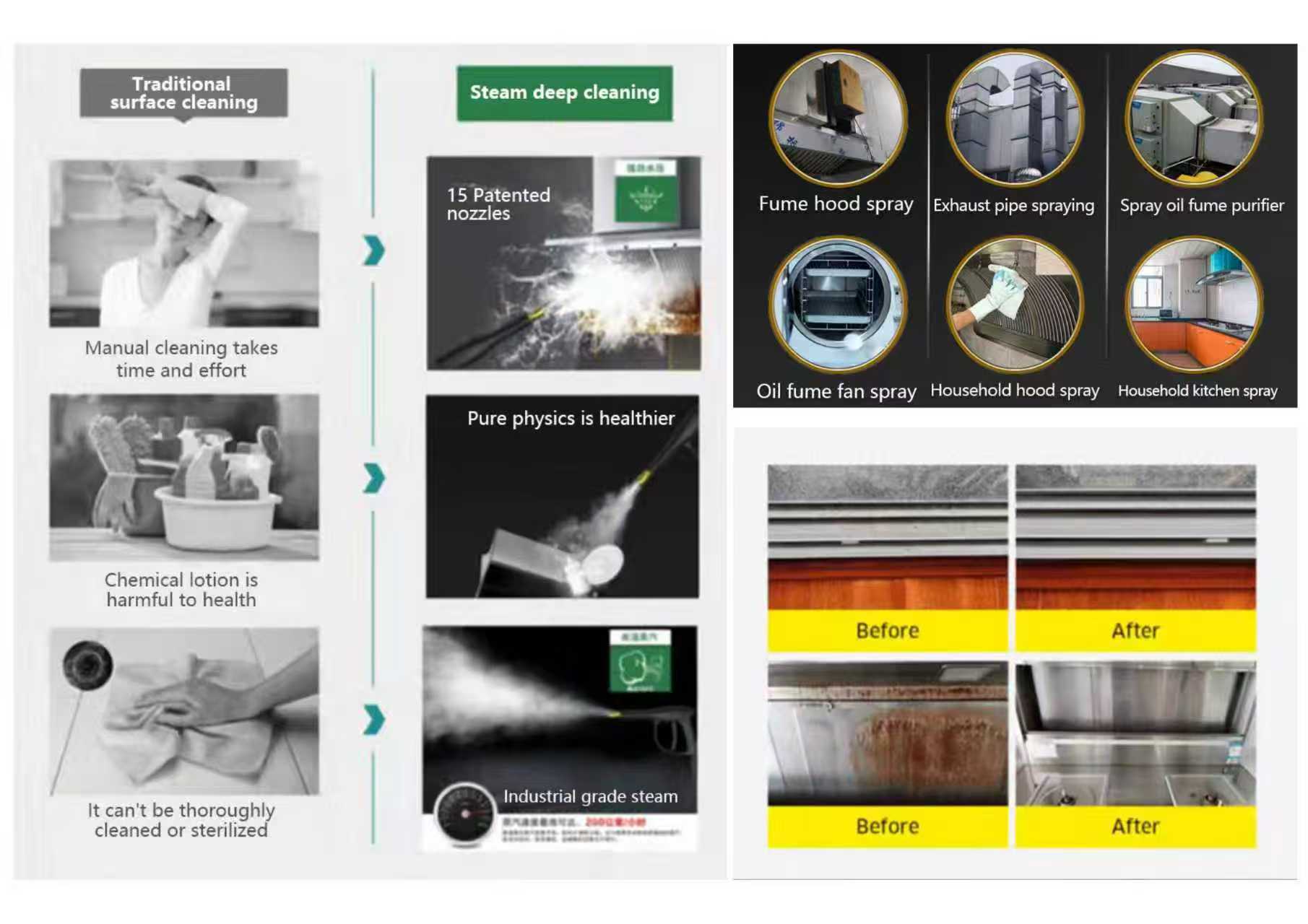

The spray machine excels in scenarios with heavy, strongly adhered grease where traditional cleaning is inefficient. Typical applications include:

| scenario Type | Specific Application Objects | Pain Points |

| Catering/Kitchen | Exhaust ducts, range hoods, cooktops, ovens, grease filters | Long-term accumulation of grease forms stubborn scale (e.g., old grease scale can be 5-10mm thick). Manual scraping is time-consuming, labor-intensive, and prone to damaging the equipment surface. |

| Comparison Dimension | Traditional Cleaning (Rags/Mops/Dry Sweeping) | Chemical Spray Machine (High-Temp, High-Pressure Chemical Spraying) |

| Cleaning Efficiency | Relies on manual repeated friction; stubborn grease requires multiple scrapes, taking 10-20 minutes per square meter. | Chemicals soften grease first—subsequent cleaning takes 2-5 minutes per square meter, boosting efficiency by 3-5x. |

| Cleaning Effectiveness | Only removes surface floating grease; deep-seated grease scale (e.g., "old grease" adhering to pipe walls) cannot be fully eliminated and recurs easily. | Specialized chemicals deeply dissolve grease, achieving a ≥95% cleaning rate with no residual buildup. |

| Equipment Damage Risk | Hard tools (e.g., steel wool) easily scratch surfaces (stainless steel kitchenware, precision instruments), causing rust or premature aging. | Chemicals are neutral/weakly alkaline (optional), avoiding physical scratches—preserves the original equipment finish. |

| Safety | Manual climbing/entering narrow spaces (pipes, range hood interiors) risks falls, bumps, or corrosion from strong chemicals (e.g., hydrochloric acid). | Remote/handheld operation eliminates need for dangerous area entry; chemicals are food-grade/industrial-grade (optional) with low toxicity. |

| Comprehensive Cost | Requires 2-3 laborers, long hours, and high single-session costs (labor + consumables). | Single-person operation reduces labor needs; long-term costs drop by 40%-60% due to faster cleaning and less waste. |

| Functional Parameter | Specification/Configuration | Practical Application Advantage |

| Chemical Spraying Design | Chemical agent spraying | Grease is primarily composed of triglycerides of fatty acids; combining with chemical agents accelerates softening. |

| Output Pressure | 6 bar (≈600 kPa) | High-pressure water flow atomizes the chemical agent and sprays it up to 1.5 meters (or penetrates 1-meter-long pipes), reaching deep into gaps/elbows (e.g., range hood impeller gaps, pipe diameter transitions). |

| Output Flow Rate | 7 L/min | Large flow rate ensures wider area coverage per unit time, reducing repeated spraying and improving efficiency. |

| Dual Pump Design | Main pump + standby pump alternating use | Prevents overheating from continuous single-pump operation, extending pump life by >30%; enables instant switching to the standby pump during temporary failures, minimizing downtime. |

Our chemical spray machine, paired with cleaning robots, uses precision chemical spraying technology to solve longstanding pain points of traditional grease removal: low efficiency, poor results, and equipment damage. Backed by 59 rigorous tests and the reliability of dual engines, it ensures long-term stable performance even in complex environments. Combined with user-friendly design (lightweight build, multi-mode spraying) and robust service support (quick after-sales), we deliver an efficient, worry-free, and durable grease cleaning solution for users.