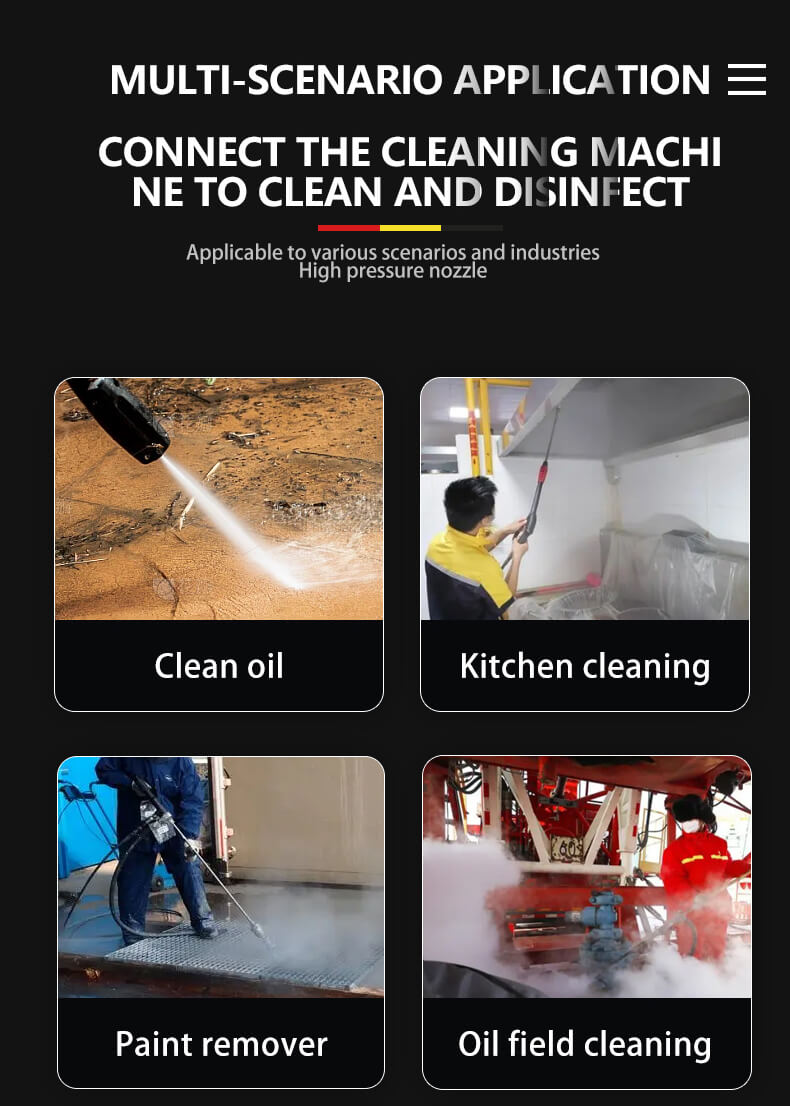

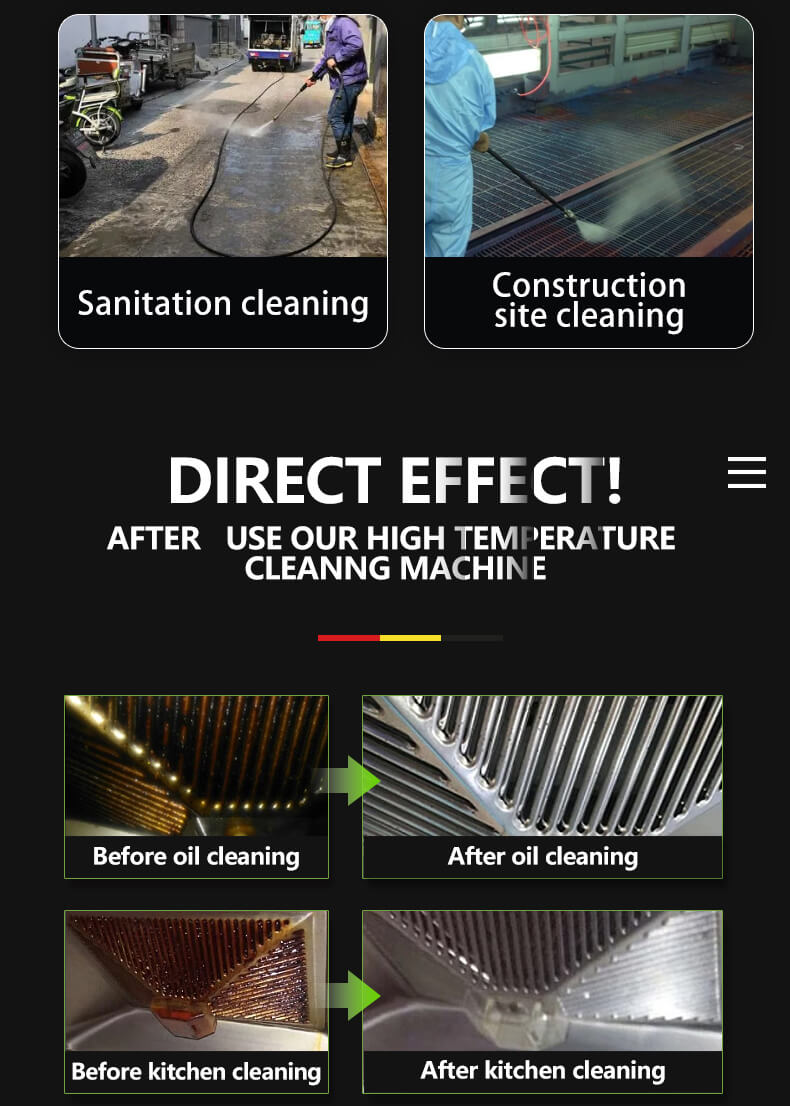

This product is a diesel-powered high-temperature liquid heating equipment that leverages a diesel combustion heating system to rapidly raise water temperature to an adjustable range of 0–90°C. It precisely delivers heated fluid through multi-stage pressure nozzles, solving the core issues of traditional electric heaters—including slow heating, low efficiency, and uncontrolled temperatures.

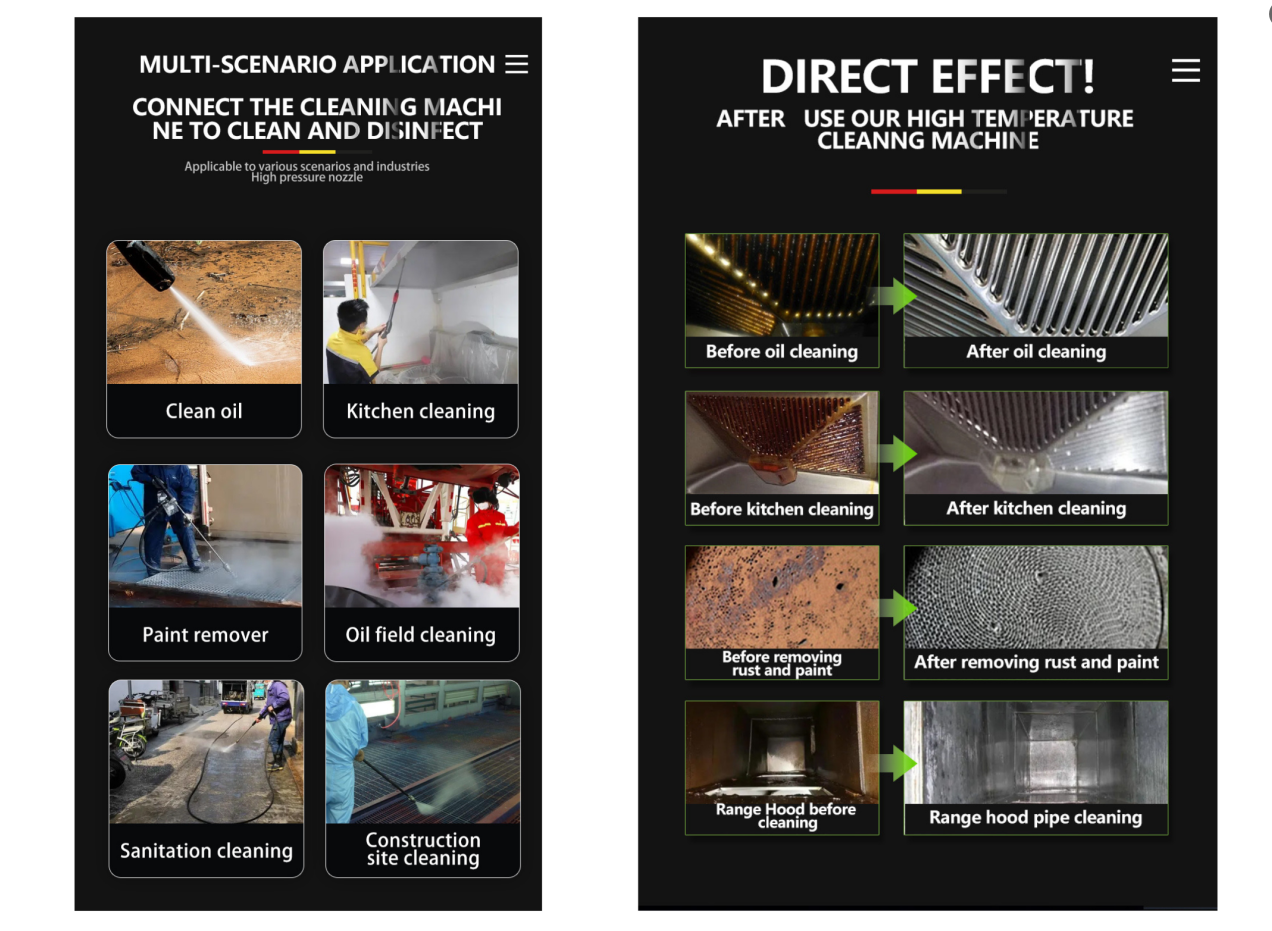

Positioned as a portable, efficient, and flexible thermal energy solution, it targets scenarios requiring high-temperature cleaning or degreasing—where traditional electric equipment falls short on mobility, speed, or temperature precision.

| Scenario Type | Specific Application Objects | Core Pain Points | Value Our Machine Delivers |

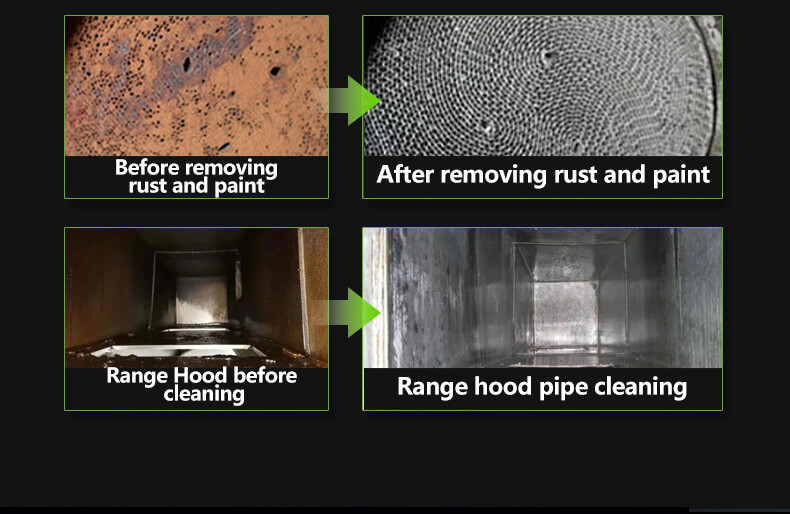

| Catering/Kitchen Cleaning | Exhaust ducts, range hoods | Requires high temperatures (80-90°C) to soften old grease buildup—but electric heaters rely on power outlets (hard to move), and manual scraping is time-consuming/laborious. | Diesel-powered: heats to 90°C in 20 seconds. Paired with G36 or G31robot, it delivers high-temperature water jets + precise multi-nozzle spraying—boosting efficiency by 5x. |

Core functions

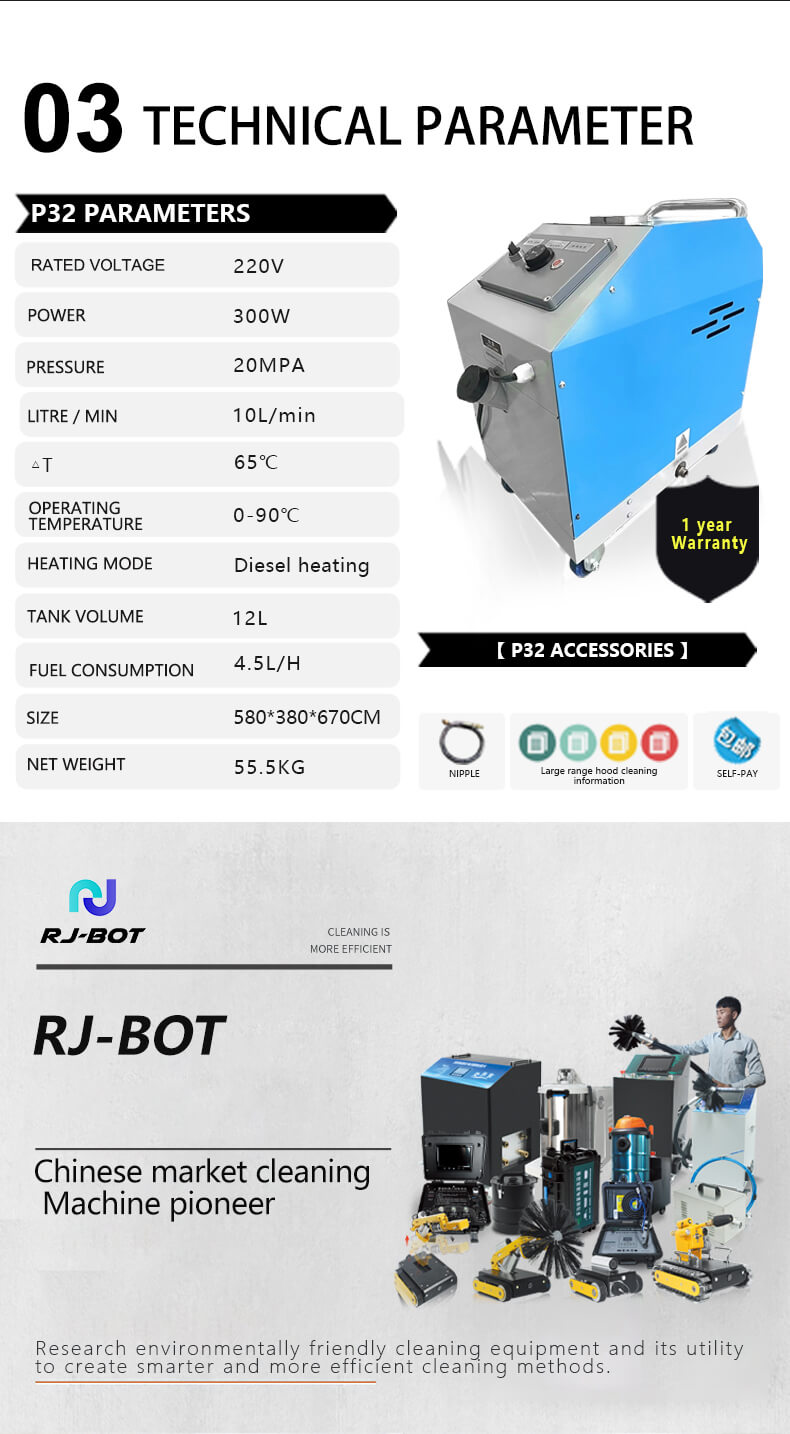

| Functional Parameter | Specification/Configuration | Technical Analysis & Advantages |

| Heating Method | Diesel Combustion Heating | Diesel has a high calorific value (≈46MJ/kg) and combustion efficiency (≥90%), saving 30% energy vs. electric heating. Indirect heat exchange prevents liquid contamination, outputting clean high-temperature fluid. It can also pair with the P40 high-pressure machine to rapidly heat water up to 200 bar. |

| Temperature Control | Adjustable 0–90℃ | Precise temperature control meets diverse needs: low temps (30–50℃) for sensitive equipment (e.g., plastic pipes); high temps (70–90℃) for stubborn grease. Avoids energy waste from overheating. |

| Heating Speed | Reaches operating temp in 20 sec (cold start); peaks at 90℃ in 30 sec | Rapid heating cuts wait time—ideal for short tasks (e.g., 1-hour post-lunch restaurant cleaning)—and boosts daily work capacity. |

| Power Core | Pure Copper Motor | Pure copper coils offer high conductivity (≥97%) and heat resistance (no deformation at 180℃). Lifespan is twice that of ordinary aluminum motors (≥5000 hours), reducing maintenance costs. |

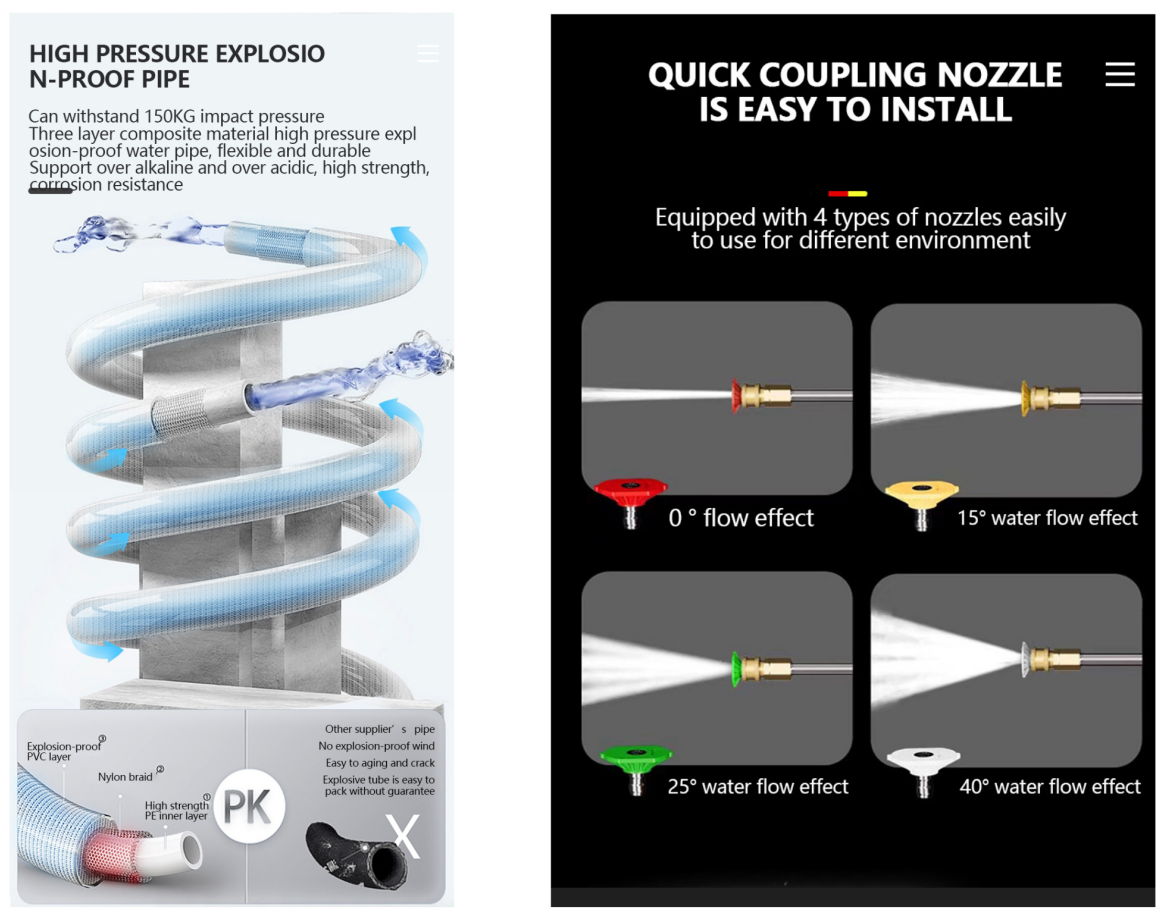

| Injection System | Multi-Stage Pressure Nozzles (0°, 15°, 25°, 40°) | Four nozzle angles cover all tasks: pipe elbows, floor cleaning, wall grease removal, and crevice spraying. No equipment swaps needed—cuts procurement costs by 50%. |

![]()

Why Choose Our Diesel High-Temperature Heating Machine?

Unlike electric heaters tied to power outlets, our machine runs on diesel—delivering rapid performance: it reaches operating temperature in 20 seconds (cold start) and hits a 90℃ peak in 30 seconds. This slashes single-task time by 40% compared to traditional electric heaters (which require 10-15 minutes of preheating), making it ideal for time-sensitive jobs like post-lunch restaurant cleanups or factory shift changes.

Whether you’re battling tough grease in kitchen exhaust systems, dissolving stubborn scale in industrial workshops, or deploying for emergency cleanups, it excels as a cost-effective thermal workhorse—helping users cut costs and boost efficiency.

Note: It pairs seamlessly with our P40 high-pressure machine. For grease removal in oily environments, high-temperature, high-pressure clean water is the ultimate solution.