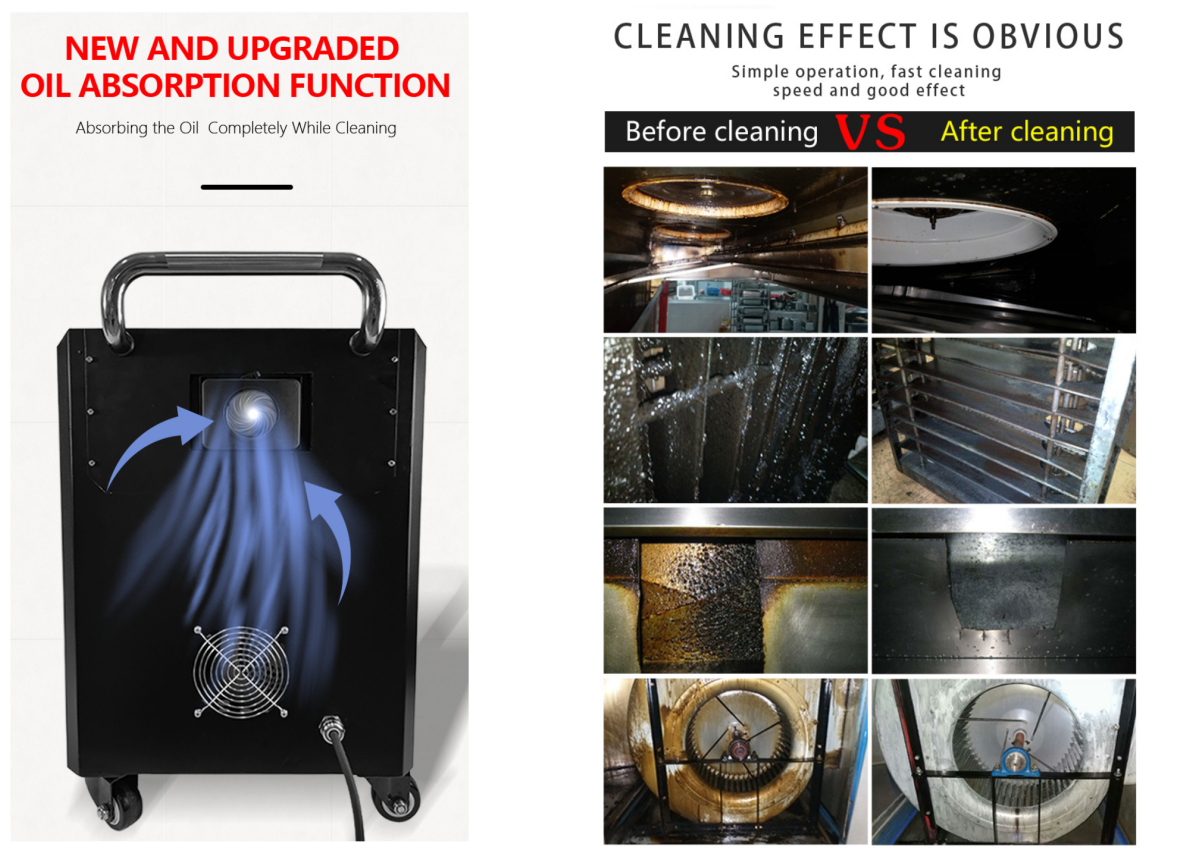

This product is an integrated high-pressure cleaning and vacuum grease/dust removal device that combines a high-pressure flushing system with a vacuum recovery system to enable a closed-loop workflow: first, high-pressure removal of stubborn grease; then, simultaneous or independent vacuum extraction of dissolved grease, debris, and wastewater.

Unlike traditional standalone high-pressure cleaners (which require additional sewage suction equipment) or vacuum grease removers (which lack flushing capabilities), our integrated design eliminates the need for secondary treatment of waste oil, wastewater, and debris post-cleaning. It is purpose-built for scenarios demanding efficient, eco-friendly handling of stubborn grease and oily waste.

| Scenario Type | Core Pain Points | Value Our Machine Delivers |

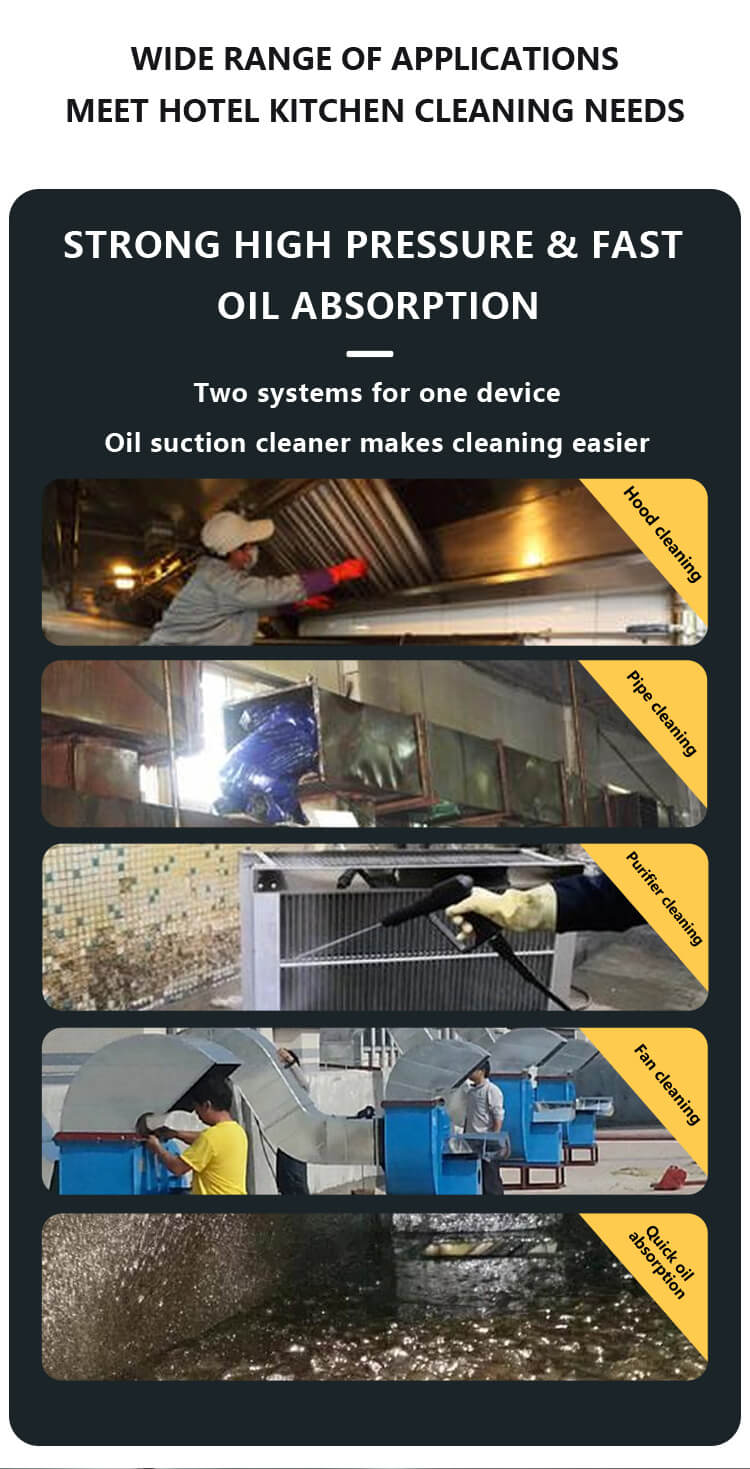

| Catering/Kitchen | Grease mixes with food residue; post-high-pressure flushing, oil-laden wastewater needs separate collection (to avoid drain blockage). Manual scraping is inefficient and leaves residues. | High-pressure flushing softens grease → vacuum simultaneously extracts wastewater, grease, and residue, preventing drain clogs. Completes "clean + collect" in one pass, slashing time by 60%. |

| Industrial Equipment/Workshops | Mechanical grease blends with iron filings/dust to form an adhesive layer. Post-flushing, waste oil and filings scatter on the floor, requiring secondary cleaning. Humid environments pose electric shock risks. | High-pressure flushing strips away grease and filings → vacuum removes mixed debris, leaving zero residue. Features leakage protection + explosion-proof hoses to adapt to humid industrial settings. |

| Functional Parameter | Specification/Configuration | Practical Application Advantage |

| Power System | 4000W high-efficiency engine | Delivers robust power to support simultaneous full-load operation of the high-pressure pump (flushing) and vacuum pump (recovery), preventing pressure/suction drops from insufficient power. |

| Pressure Control | Adjustable pressure valve design, max 20 MPa (megapascals) | Wide adjustable pressure range suits different materials (e.g., low pressure for delicate equipment, high pressure for stubborn grease). |

| Safety Protection | Leakage protection device | Automatically cuts power to prevent electric shock in wet environments; waterproof design safeguards the motor from water ingress damage. |

| Delivery System | 15-meter pressure-resistant & explosion-proof steel wire hose (extends to 25m with G36 robot) | Explosion-proof construction prevents high-pressure air/grease leaks; long hose covers large spaces (e.g., long pipes) without frequent repositioning. |

| Vacuum Recovery System | Dual-mode: Vacuum oil suction + Dust collection | All-in-one design adapts to both liquid waste (oil) and solid debris—no need for separate tools. |

| Dual Vacuum Pump Design | 1 high-pressure pump + 2 independent vacuum pumps | Mutual backup: Failure of one pump does not disrupt the other’s function, minimizing downtime. |

Traditional solutions require two separate devices—a high-pressure cleaner and a vacuum sewage truck—resulting in cumbersome operations, time-consuming equipment transfers, and inefficient workflows.

Our product stands out with its integrated design: by synergizing high-pressure flushing and vacuum recovery, it eliminates the pain points of traditional equipment—including low efficiency, secondary pollution, and high safety risks. Powered by a 4000W high-efficiency engine, reinforced with multiple safety protections (e.g., leakage prevention, waterproofing), and built for durability, it delivers faster, more efficient cleaning (no need for secondary waste handling), uncompromised safety (ideal for wet, hazardous environments), low long-term costs (reduced labor, fewer replacements).

It is the ultimate integrated solution for grease and oil waste management—combining power, reliability, and sustainability in one device